Membrane Switch Defined

What is a Membrane Switch?

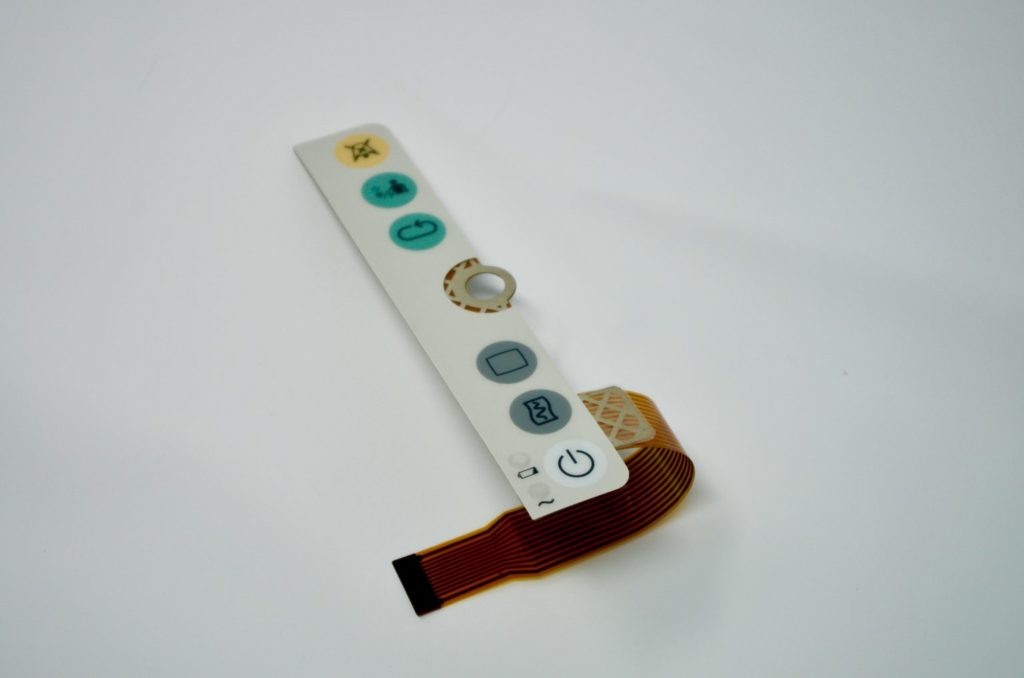

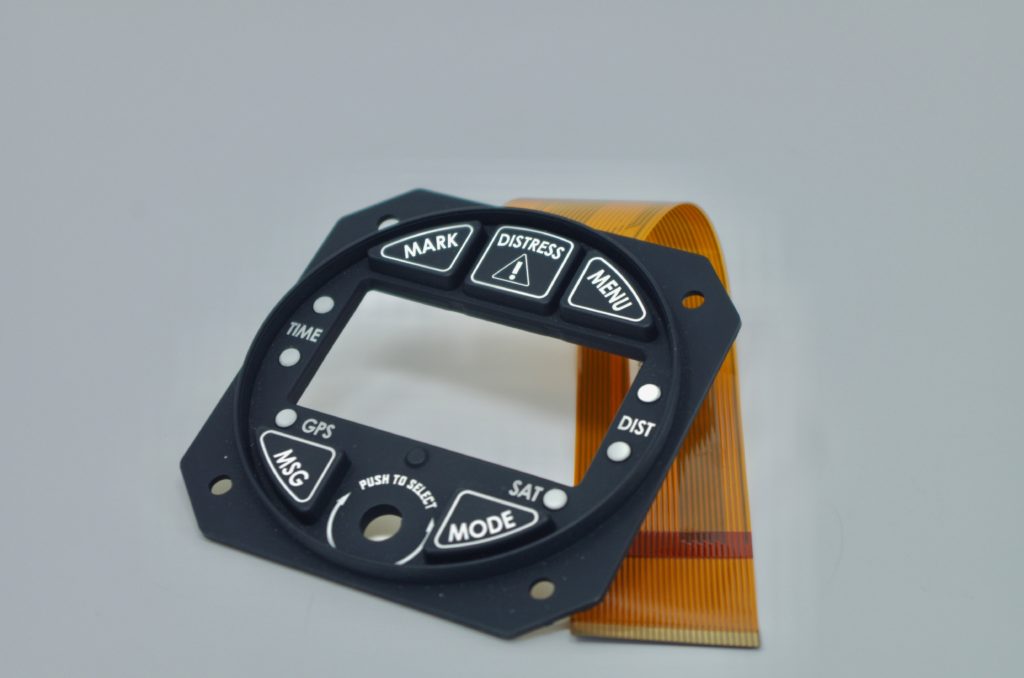

A membrane switch is an interface between man and machine, enabling an operator to communicate with equipment, instrumentation, or machinery. A membrane switch is a printed or etched electronic circuit that uses pressure to open and close a circuit. The membrane switch circuitry can be: screen printed using conductive inks which are typically made of silver or carbon, etched copper on Kapton, or can be printed circuit board based. The membrane switch overlay is typically made of polyester, polycarbonate, or molded silicone rubber. Membrane switches are part of a range of devices considered to be user interfaces or human machine interfaces (HMIs) along with touch screens and mechanical switches.

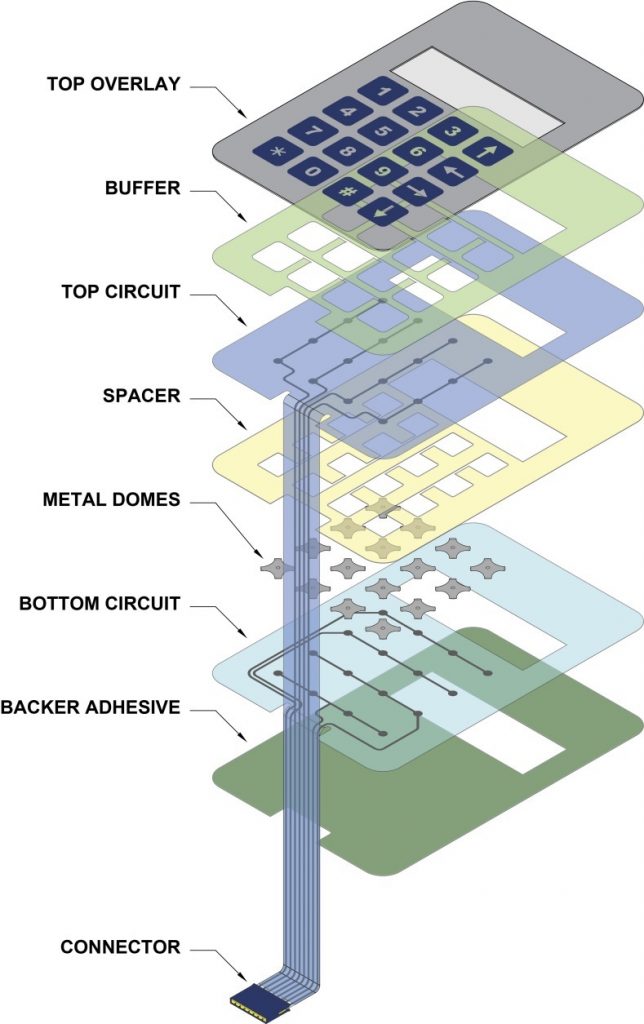

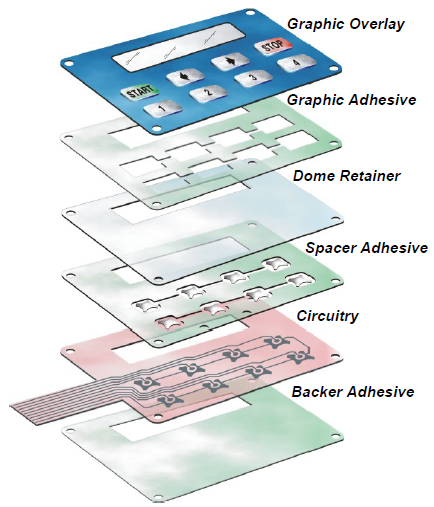

Membrane Switch Construction

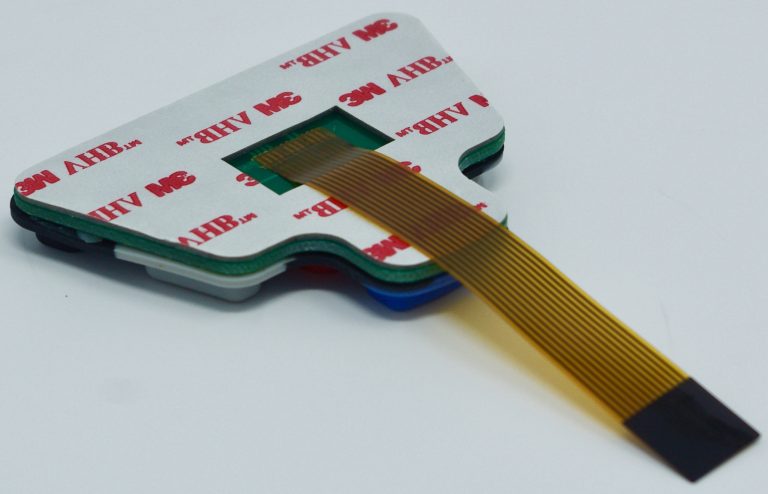

A typical membrane switch assembly typically consists of six to seven main layers:

- Graphic Overlay – Graphic overlays are typically constructed of polyester, the material of choice due to its superior chemical resistance and flex life compared to polycarbonate. CSI can either digitally print, screen-print, or employ a combination of both methods to insure you get the right colors, textures, and finishes your Silver Flex membrane switch design requires.

- Overlay Adhesive – The overlay adhesive layer bonds the graphic overlay to the top circuit layer. This overlay adhesive is typically an acrylic adhesive, selected for its durability and ability to maintain adherence in atypical environments, such as moist environments.

- Top Circuit Layer – Typically a .005″ – .007″ heat-stabilized, polyester printed layer with silver-filled, electrically conductive inks and dielectric inks. This layer can also encapsulate metal domes or incorporate polydomes, which are used to achieve tactile feedback, an important design consideration impacting usability.

- Circuit Spacer – This layer separates the top circuit from the bottom circuit, so the switch remains normally open until the keypad is pressed. The circuit spacer is a polyester spacer with adhesive on both sides.

- Lower Circuit Layer – The lower circuit layer is typically a .005″ – .007″ heat-stabilized, polyester-printed layer with silver-filled electrically conductive inks and dielectric inks. This layer terminates as a flexible tail that serves as the interconnect to controller PCB’s or other electronics.

- Rear Adhesive Layer – This adhesive layer bonds the entire membrane switch package to the product enclosure, housing, or to a rigid support panel. CSI can specify the appropriate adhesive type and thickness to bond your membrane keypad to your equipment.

- Rigid Support Layer – This optional layer can add structural integrity to the membrane switch assembly. Materials can be aluminum, FR-4, steel, etc. Mounting hardware such as studs and standoffs can also be utilized in this layer.

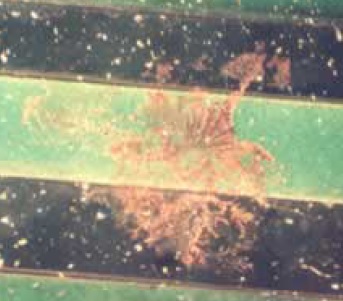

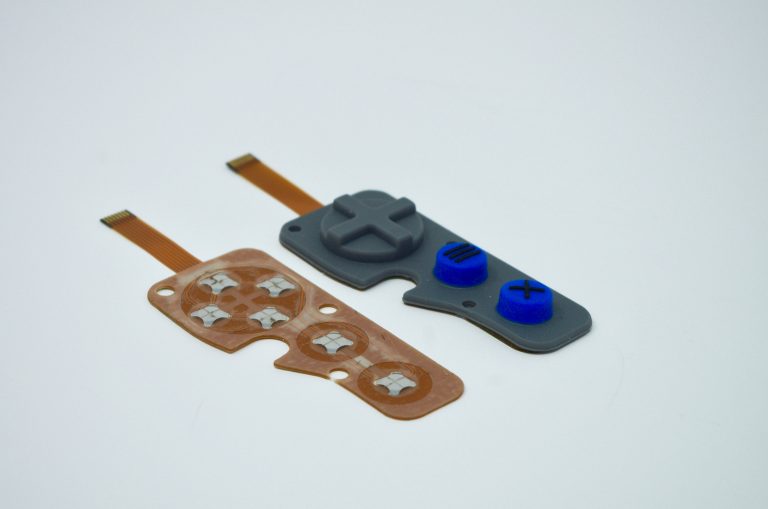

Copper Flex Membrane Switches

The Copper Flex Membrane Switch constructions are ideal for smaller designs, where space is at a premium, or where dense circuit patterns or trace routing limitations exist. Copper Flex membrane keypads utilize silver or copper layers which are laminated to a dielectric layer and etched away.

This switching technology combines the ability to accommodate the complex circuit patterns of a FR4 rigid printed circuit board with the flexibility of a membrane switch. Copper Flex keypads also have the advantage of being able to “hard” solder both active and passive components into the assembly, making it a good choice in high-vibration environments.

Copper Flex membrane switch panels can be produced using polyester or polyimide (Kapton) as the base material depending on your interface requirements. A very thin sheet of copper is laminated to the flexible film substrate then chemically etched away, leaving copper traces.

Copper Flex membrane switches offer you a variety of design options:

- Single and double sided designs

- Lower electrical resistance and higher conductivity vs. traditional Silver Flex membrane switches

- Tight trace routing capabilities

- Thin profile and flexibility of Silver Flex membrane switch

- Plating options can be tin-lead, nickel, or gold

- Tactile and non-tactile with either metal or polyester tactile domes

- LED’s and other components can be soldered

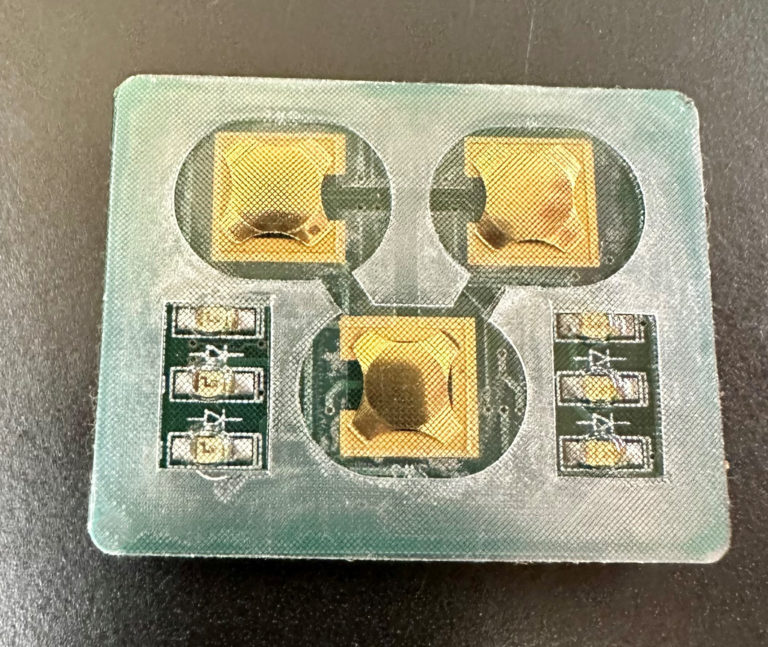

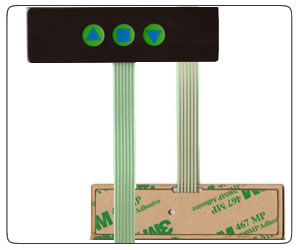

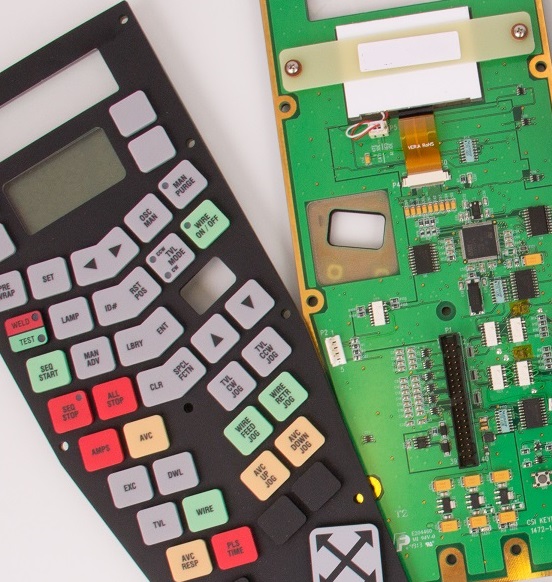

PCB Based Membrane Switches

The PCB Membrane Switch construction utilizes a printed circuit board (PCB) which can serve a dual purpose in your membrane switch design. PCB Switches are typically more costly than Silver Flex membrane keypads, but can accommodate dense circuit patterns and more complex circuit patterns compared to Silver Flex membrane keypads.

A PCB membrane switch also allows the electronic components to be “hard-soldered” into the PCB, whereas membrane switch components are placed using a polymer thick film conductive paste. With a PCB membrane switch, the PCB can serve as a rigid backer, and is also a very durable and reliable method to incorporate LED’s, resistors, LCD’s and other components.

PCB membrane keyboards offer you a variety of design options:

- Tactile and non-tactile with either metal or polyester tactile domes

- Pillow or rim-embossed graphic overlays

- Embedded LED’s that are soldered directly into the PCB

- Fiber Optic backlighting

- EL – (Electroluminescent backlighting)

- Rigid backers such as aluminum and FR4

- EMI/RFI shielding

- Unlimited choice of connectors, which can be soldered directly into the PCB

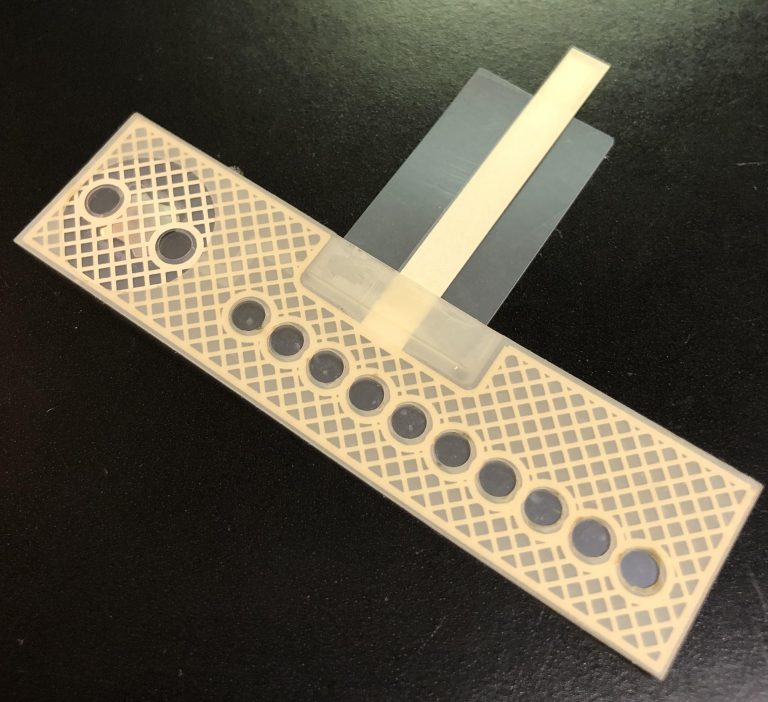

Silicone Elastomer Rubber Keypads

Silicone rubber keypads use compression-molded silicone rubber with conductive carbon pills or with non-conductive rubber actuators. They have exceptional resistance to extreme temperatures and aging, making them an ideal choice if reliability is a prominent concern due to likely environmental influences.

A rubber membrane switch uses compression-molded silicone rubber with conductive carbon pills or with non-conductive rubber actuators. Rubber keypads are relatively inexpensive on a per-piece basis, but require fairly expensive tooling, usually making them a design choice for higher-volume projects.

Silicone rubber keypad switches have numerous features that set this type apart from other traditional membrane switch designs. Some of the main differentiating features of this type make the silicone rubber keypad switch an ideal choice for applications requiring more durability or better resistance to exposure to moisture, chemicals, or other compounds.

Some of the primary distinctive features of silicone rubber keypad switches include:

- Work as a conductive shorting device for Silver Flex membrane switches, PCB membrane switches, and Copper Flex membrane switches

- Can utilize carbon pills, non-conductive rubber actuators, or stainless steel tactile domes

- Actuation forces and switch travel can be customized

- Any shape or size can be designed

- Multiple colors can be achieved by flow molding the color during the compression-molding process

- Rubber keypad top graphics can be customized by screen-printing

- Rubber keypad switches can be PU spray-coated for enhanced durability

- Rubber membrane switches have excellent weatherability for outdoor use

- Can be designed to seal the keypad assembly from moisture and contaminants

- Silicone rubber is resistant to chemicals and moisture

- Laser etching the rubber keypads can allow for backlighting individual keypads

- Backlighting options