Sealing

Many of CSI Keyboards’ customers require environmentally sealed switches and keypads built to last in extreme and harsh environments. CSI Keyboards has over 35 years of experience designing keypads that are completely environmentally sealed and switches that need to meet specific requirements for Water, Temperature, Humidity, Dirt, Dust, Altitude, Impact resistance, Vibration, and Chemical resistance.

Some of our technologies for environmentally sealing keypads include the Seal Frame design, rubber keypad sealing designs, copper flex circuitry, environmentally resistant polyester technology, and other proprietary sealing techniques.

Membrane Switch Sealing

UV Resistant

Environmentally Sealed

Temperature Resistant

Chemical Resistant

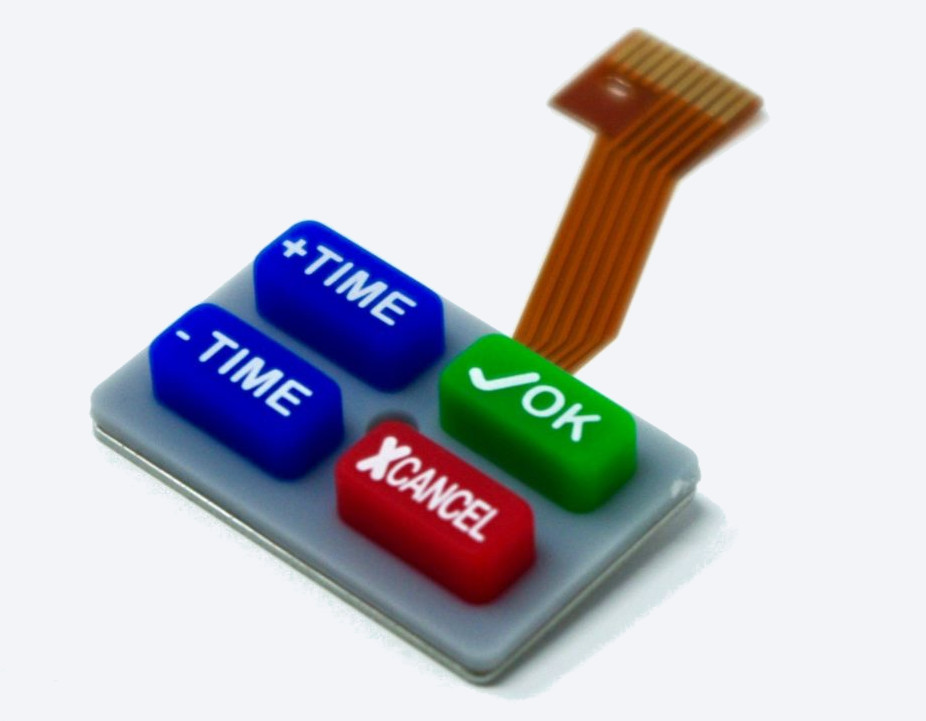

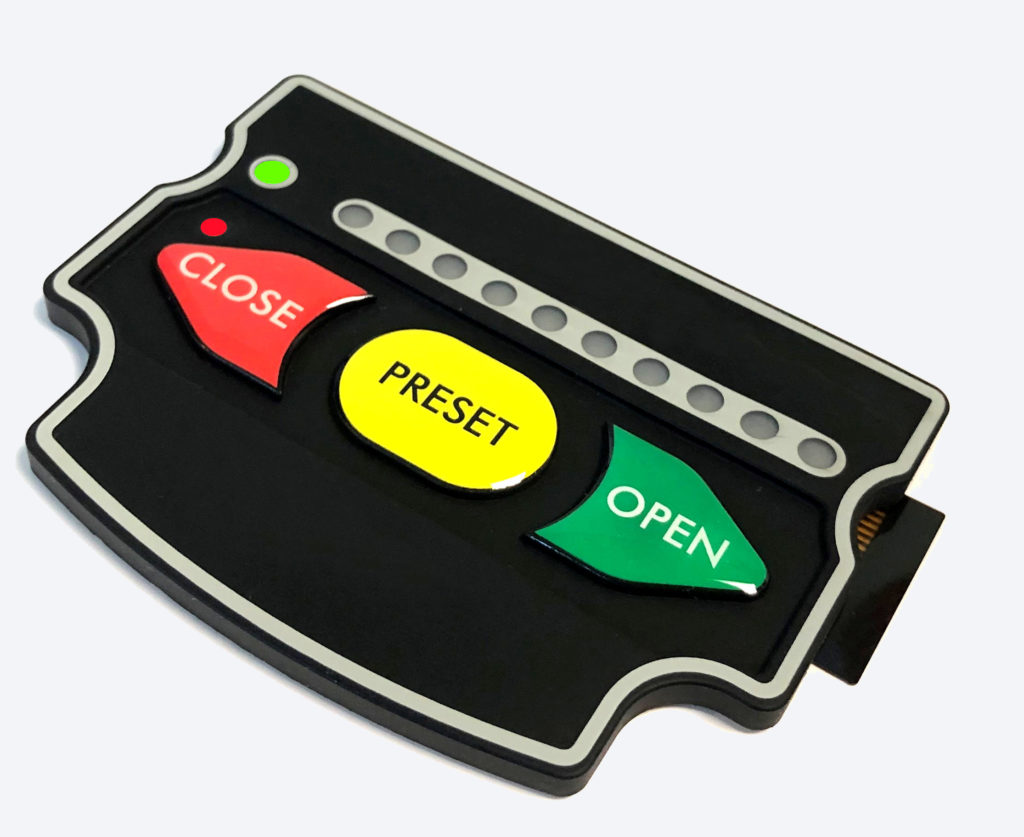

Parking Meter Keypad Assembly

This application was a parking meter that was currently using a non-tactile capacitive switch using molded polycarbonate. The customer’s end goal was to create a keypad that had raised profile and tactile feedback with each button press, while maintaining a waterproof seal against the weather’s elements. This keypad can now be seen on city streets across the country.

Characteristics:

- Molded silicone rubber keys with UV resistant coating

- Tactile domes to improve tactile feedback

- Copper flex circuit

- Rubber designed to provide a water tight seal

- Metal backer for mounting and rigidity

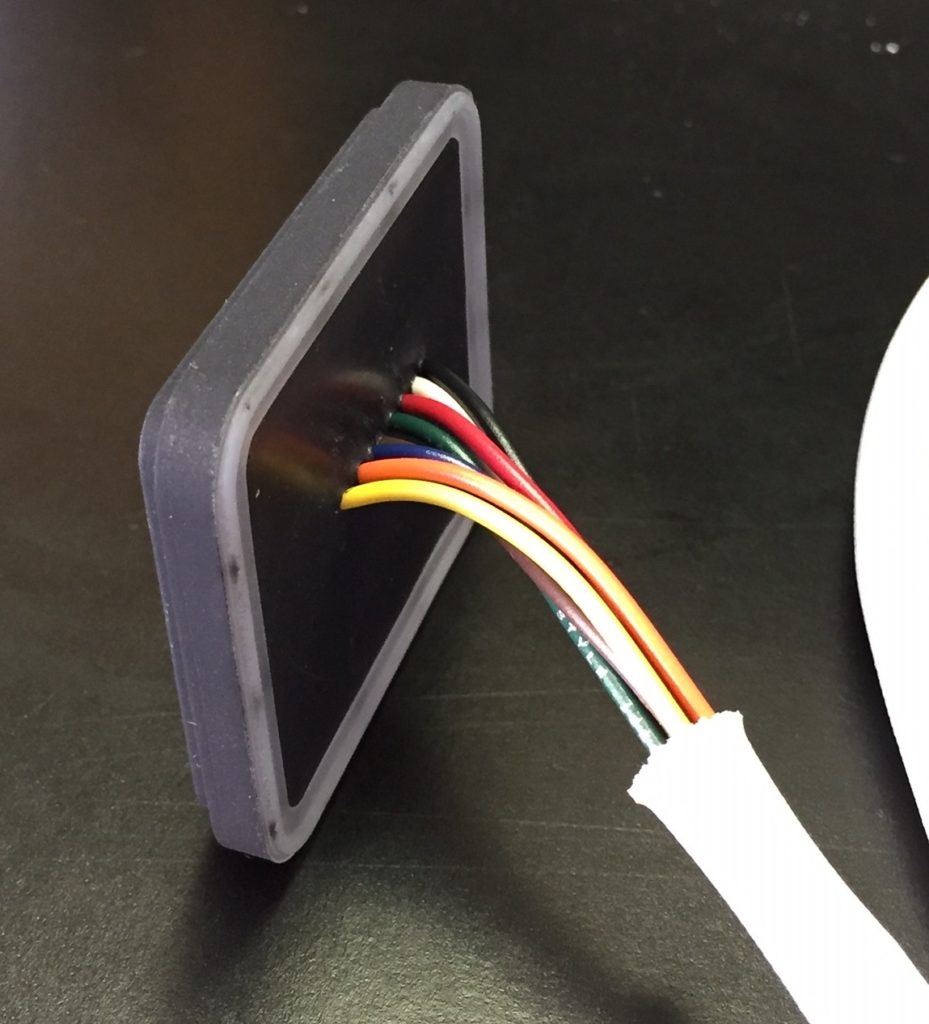

- Flex tails exit rear of assembly for connection

Copper Flex Circuitry

CSI Keyboards uses copper flex circuitry in the majority of our keypad designs due to its excellent dielectric strength, thermal stability, chemical resistance and flexibility. Copper flex, also known as Kapton circuits, has become the superior choice over printed silver especially for outdoor applications. A printed silver circuit can be replaced with a copper and polyimide circuitry construction with minimal additional cost. Copper flex circuitry construction designs offer a significant advantage over printed silver.

Copper Flex membrane switch panels are produced using polyimide (Kapton) as the base material. Copper flex switches are manufactured by laminating a thin sheet of copper to a flexible film substrate. The copper is then chemically etched away, leaving the copper traces. An additional layer of polyimide is laminated to the circuit leaving the gold contacts exposed.

Advantages of copperflex over printed silver circuitry is as follows:

- Improved creasability – the ability to fold or crease without causing open circuits which you are susceptible to using silver ink

- Ability to put solder components directly on flex, better adhesion than bonding to silver ink

- Much more resistant to thermal shock

- No potential problems with silver migration

- Greater conductivity

- Lowering the closed loop resistance and switch bounce will be reduced by gold plating the contacts. We will have a gold to gold contact with no bounce versus silver to gold dome

- Applying stiffener to tail end using heat lamination versus cold lamination which provides better adhesion and better for pinning

- Ability to have a 0.5mm pitch vs. the 1.0mm minimum with printed silver

- Tighter trace routing capabilities

The CSI “Seal Frame”

CSI Keyboards has become the go-to membrane keypad manufacturer for environmentally sealed rubber keypad designs. Sealing can be designed into the rubber and our proprietary bonding methods can also be designed in to create NEMA 2, 3 and 4 assemblies. We can design and customize gaskets per your requirements or IP standards which include both IP67 rated membrane keypads and IP68 rated membrane keypads. We have designed sealed rubber switches for marine navigation controls, medical equipment, military applications, industrial controls and food packaging equipment.

Sealed Rubber Keypad Assemblies

CSI Keyboards has become the go-to membrane keypad manufacturer for environmentally sealed rubber keypad designs. Sealing can be designed into the rubber and our proprietary bonding methods can also be designed in to create NEMA 2, 3 and 4 assemblies. We can design and customize gaskets per your requirements or IP standards which include both IP67 rated membrane keypads and IP68 rated membrane keypads. We have designed sealed rubber switches for marine navigation controls, medical equipment, military applications, industrial controls and food packaging equipment.

Proprietary Potting Solution

Sealing can be designed into the rubber and our proprietary bonding methods can also be designed in to create NEMA 2, 3 and 4 assemblies. Our proprietary potting compounds adhere to electronics such as fully populated printed circuit board assemblies and silicone rubber, providing a completely sealed interface. We can design and customize gaskets per your requirements or IP standards which include both IP67 rated membrane keypads and IP68 rated membrane keypads. We have designed sealed rubber switches for marine navigation controls, medical equipment, military applications, industrial controls and food packaging equipment.

Environmentally Resistant and High Performance Polyester & Adhesives

CSI Keyboards utilizes polyester specially formulated to resist ultraviolet light, moisture and wide variations in temperature. CSI Keyboards offers both fine and velvet polyester textures specifically designed for outdoor applications. Our membrane keypads are UV, humidity and chemically resistant.

CSI Keyboards utilizes the top of the line adhesives specially formulated to provide high bond strength to surfaces. Our adhesives are resistant to humidity, UV, water, temperature, and chemicals.