Shielding Options for Membrane Switches

Depending on the type of membrane switch design, the graphic overlay material or the molded rubber materials both have a relatively high dielectric strength and high volume resistivity. If required, a higher degree of electrical shielding can also be integrated into the membrane switch construction. The requirements can vary depending on the industry the product will be used in.

Shields can be designed for the following:

- ESD (Electrostatic Discharge)

- EMI (Electromagnetic Interface)

- RFI (Radio Frequency Interface)

CSI offers four shielding methods to protect membrane switches:

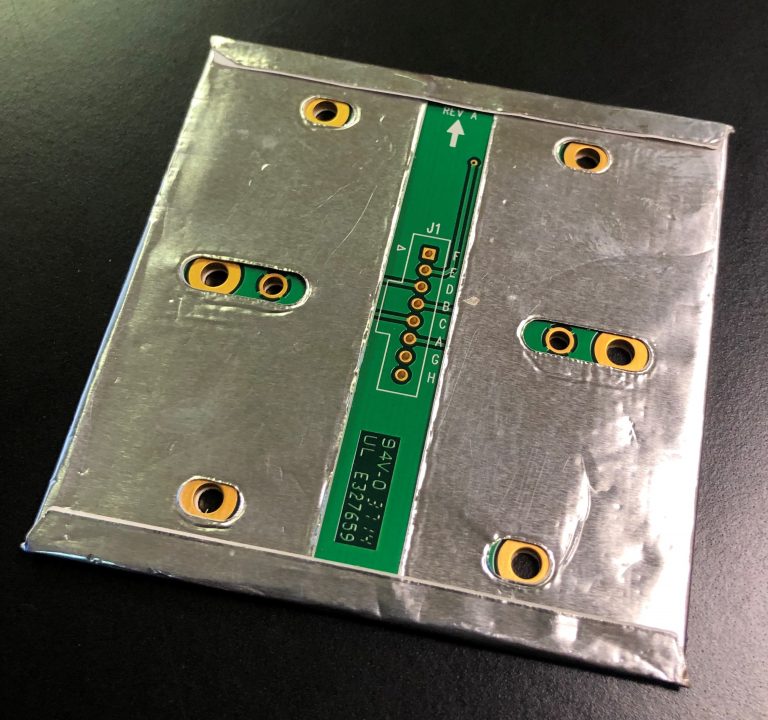

- Foil: Laminated aluminum foil and polyester.

- Transparent Film: Shielding required over windows (more costly).

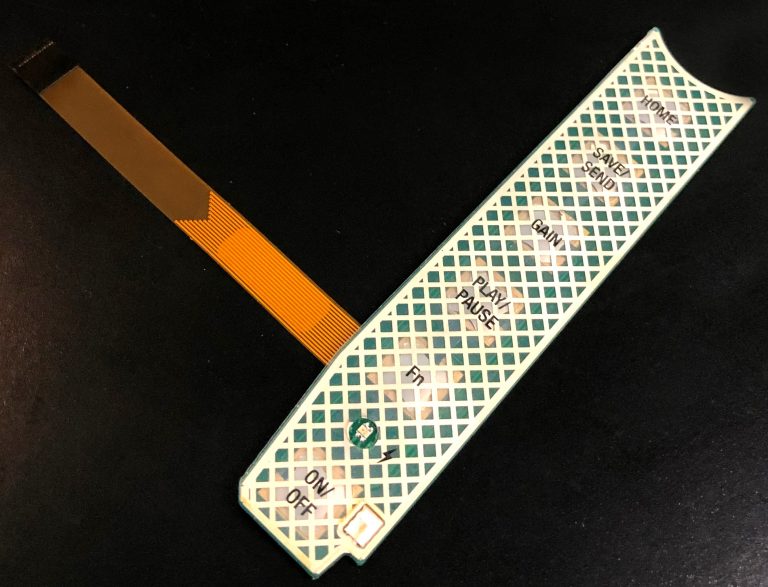

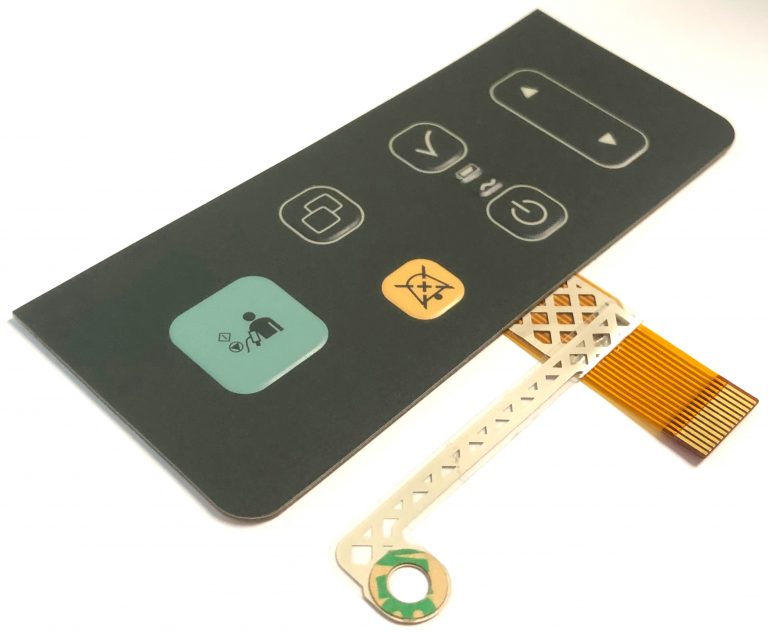

- Printed Screen: printed with silver conductive ink in a grid, bus-bar or full-coating format. Typically, the grid format is chosen because it is very reliable and does not use as much silver conductive ink as does the full-coating format.

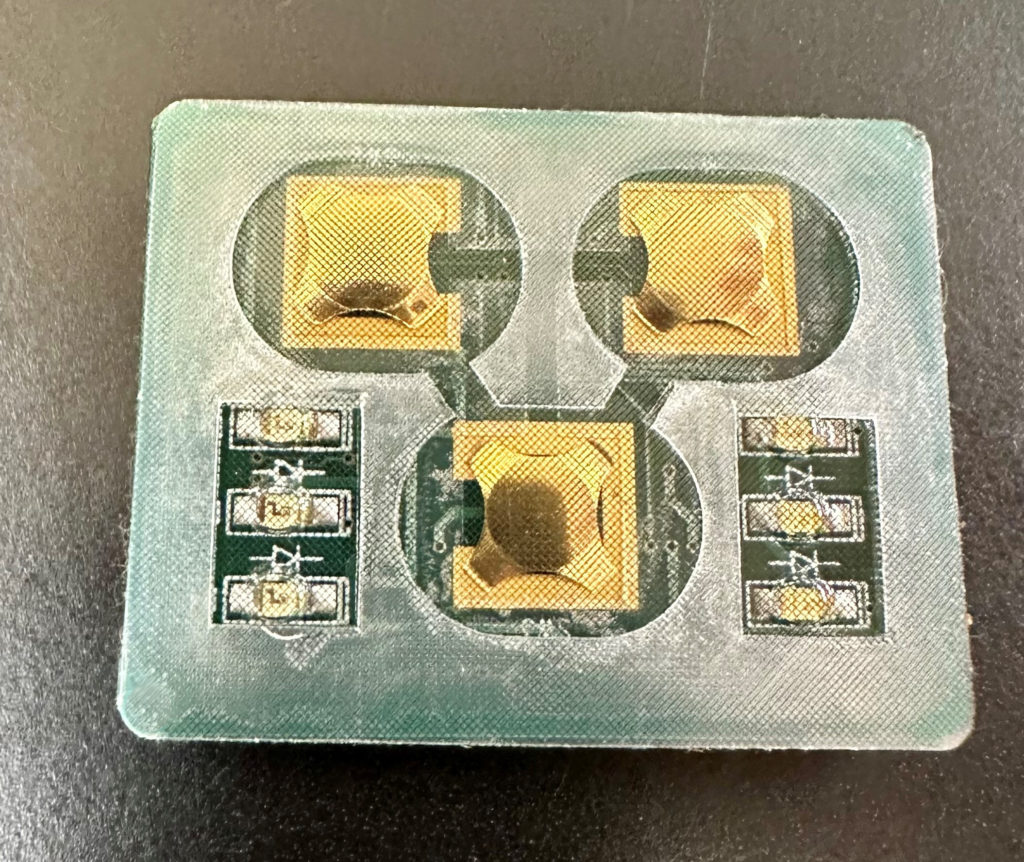

- EMI Mesh: The mesh is die-cut to the shape of the keypad and then assembled into the internal layers of the keypad assembly.

Shield Termination Methods:

- Tab: The preferred method for reliability. Can be attached to a stud or stand-off on a back panel or metal enclosure.

- Connector: Shield layer can be terminated into a pin or pins on the circuit tail connector.

- Wrap-Around: Shield layer can wrap completely around the membrane on all four sides to ground to a chassis. Although this method is very reliable, it is more costly than the other two methods due to the added labor and material necessary to execute.