How to Choose the Right Dome for a Membrane Switch

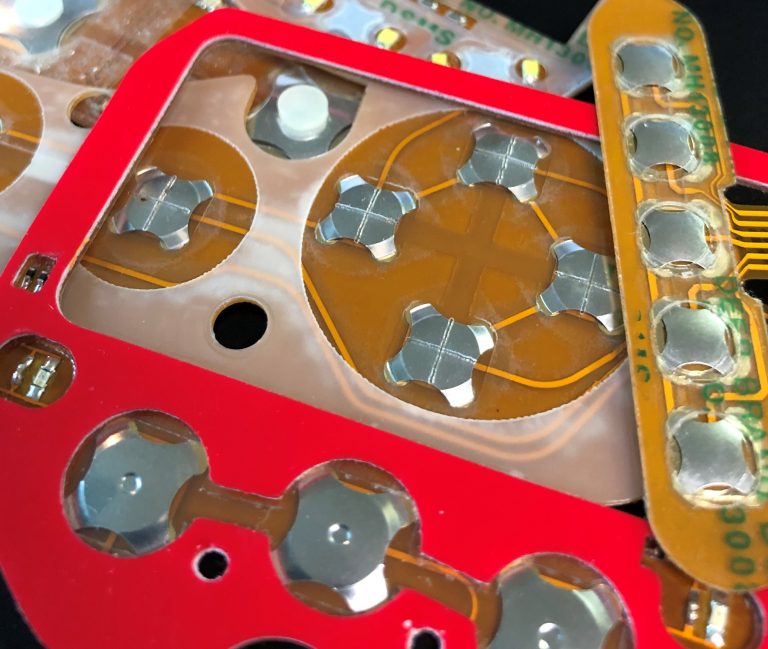

Choosing the “right” dome for a membrane switch may seem daunting, but rest assured, it is more straightforward than you might initially think. Firstly, what are metal domes? Metal domes are used in membrane switches and keypads to enable and facilitate the electrical connection from the keypad to the product itself. Or in other words, how the user of a device initiates a specific electrical function on the product.

Electrical switches are necessary in almost every HMI (human-machine interface) device or product. No membrane switch is the same and all are used in a unique environment, therefore it is critical that the most suitable dome is chosen for the specific application and environment. For instance, if the product is used in an industrial setting and the user will be wearing gloves: a dome larger in size with a higher force & stronger tactile feedback would be ideal. Or if the membrane switch will be used in a nursing home setting and the user will typically be older in age: a dome with a lighter force (easier to press) would be best suited.

Our CSI engineers will work closely with you in deciding which dome is best for your application. We understand that the tactile feel of a key is very subjective, so typically will mock up multiple sample keypads with different dome options in the prototype stage of the design. This allows our customers to make a decision through a more “hands-on” approach. It’s also important to understand that the dome happens to be one of the easiest components of the membrane switch design to change-out & replace throughout the design cycle and even after the keypad is in production (ie so you are never stuck with a specific dome).

Dome Characteristics & Options:

Size:

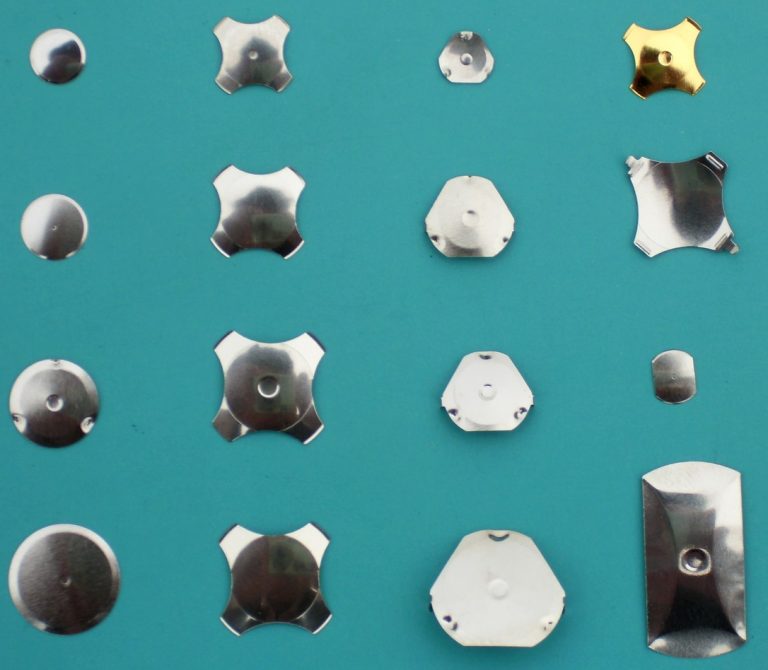

Measured in diameter and height of the dome. The size of the keys on the membrane switch will ultimately determine the size of the dome required for the application. Domes sizes range from 6mm up to 20mm. Height is dependent on size and ranges from .25mm up to 1.45mm.

Shape:

- Four legged

- Triangle

- Round

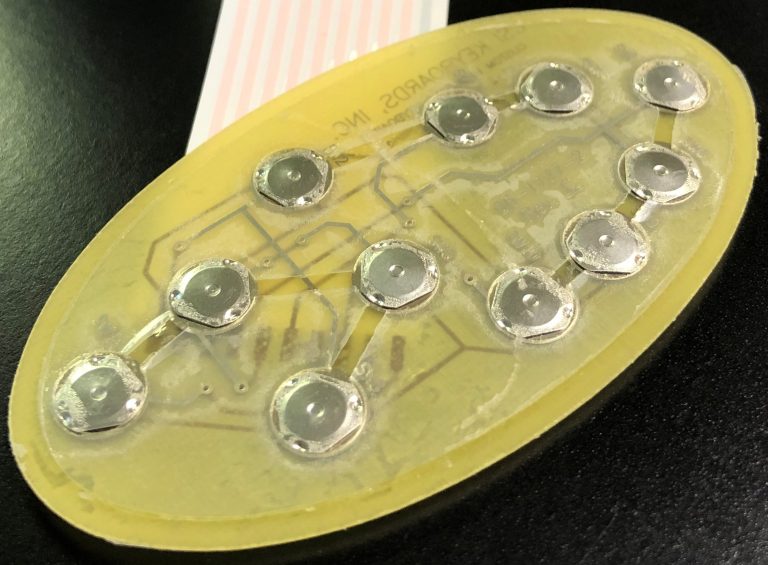

- Oblong

- Custom

Actuation Force:

The actuation force is one of the most critical characteristics when choosing a dome. Actuation or trip force is the minimum force needed to depress the dome and is measured in grams. Actuation forces range from 40g up to 2250g.

Lifecycles:

Domes have come a long way since their inception. Originally, domes were only rated for thousands of cycles. The standard for domes is now at least one million cycles, with specialized domes rated for at least five million cycles. No matter the application, there is a dome that can meet your lifecycle requirements.

Dimple or Non-Dimpled:

Looking at a variety of domes for different applications, users may notice a little dimple located in the center of the dome (see pictures to the right). The dimple is a small concave feature located on top of the dome, and can be as deep as 0.2 mm (0.008 in.). The purpose of the dimple is to provide better electrical characteristics and to reduce contact bounce..