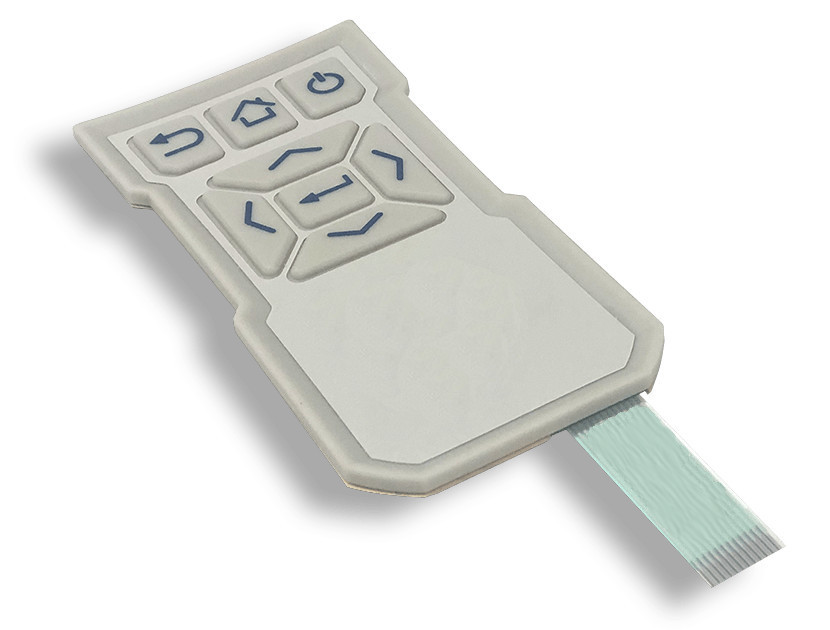

Rubber Keypads

Custom Rubber Keypads

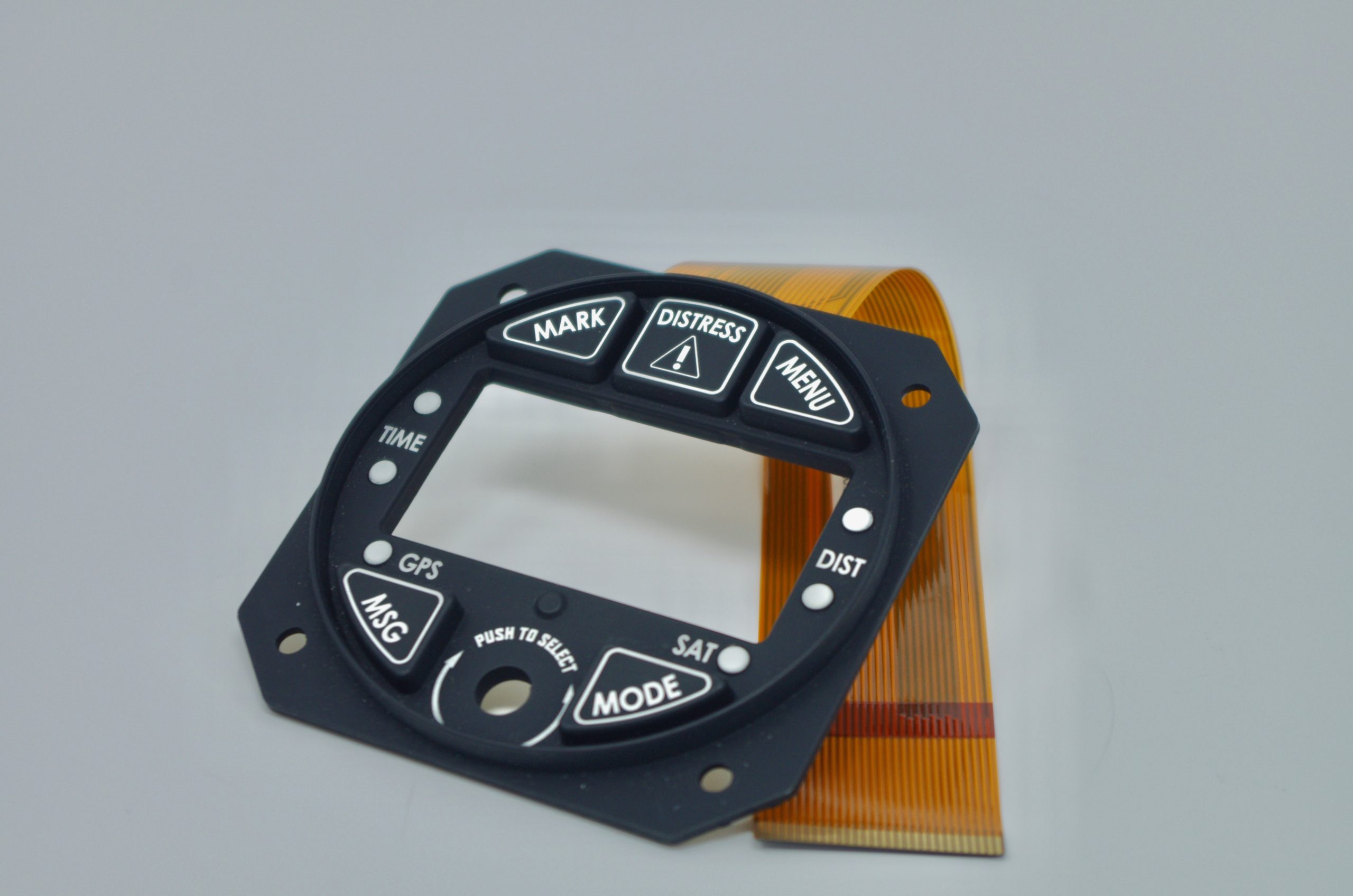

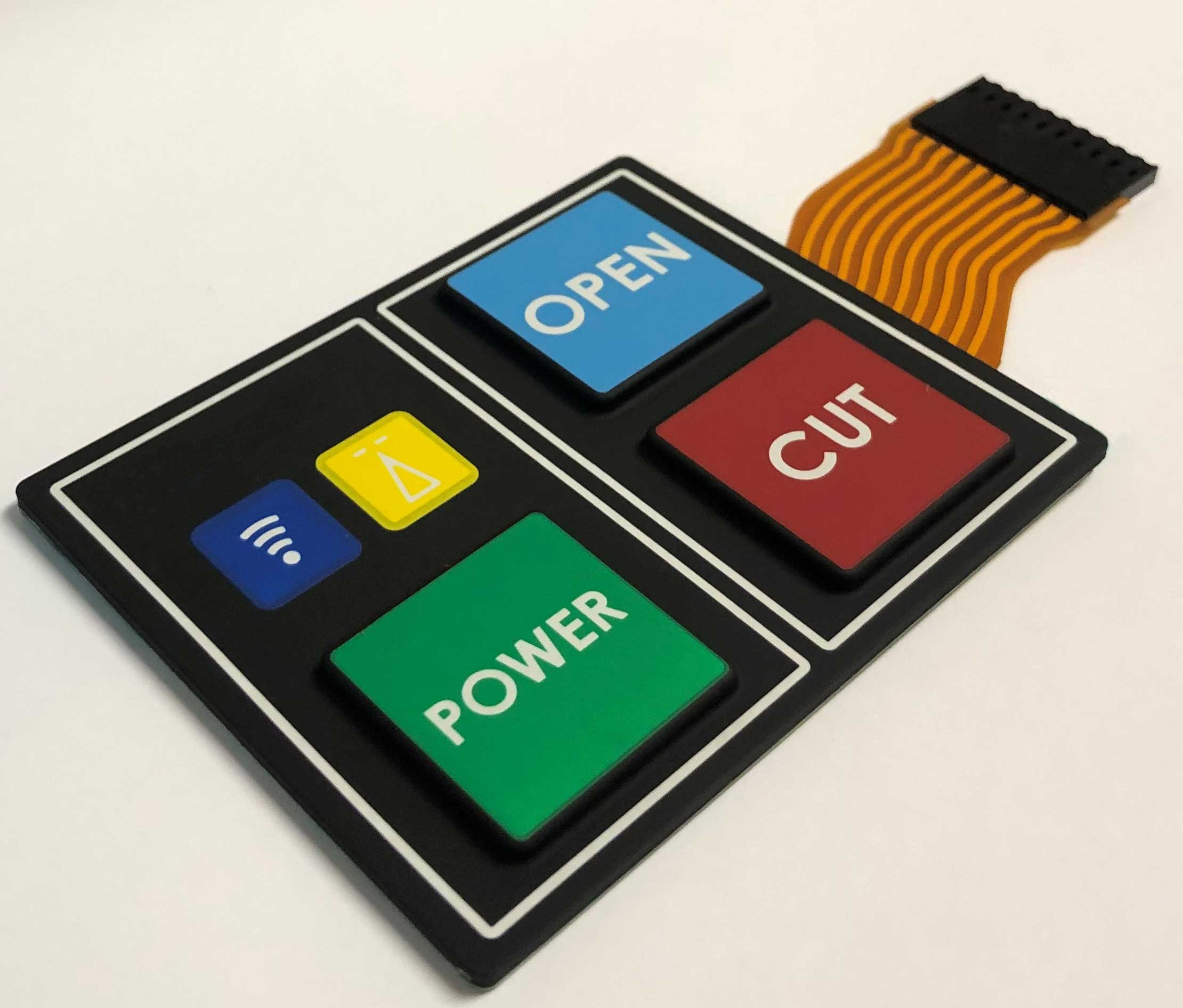

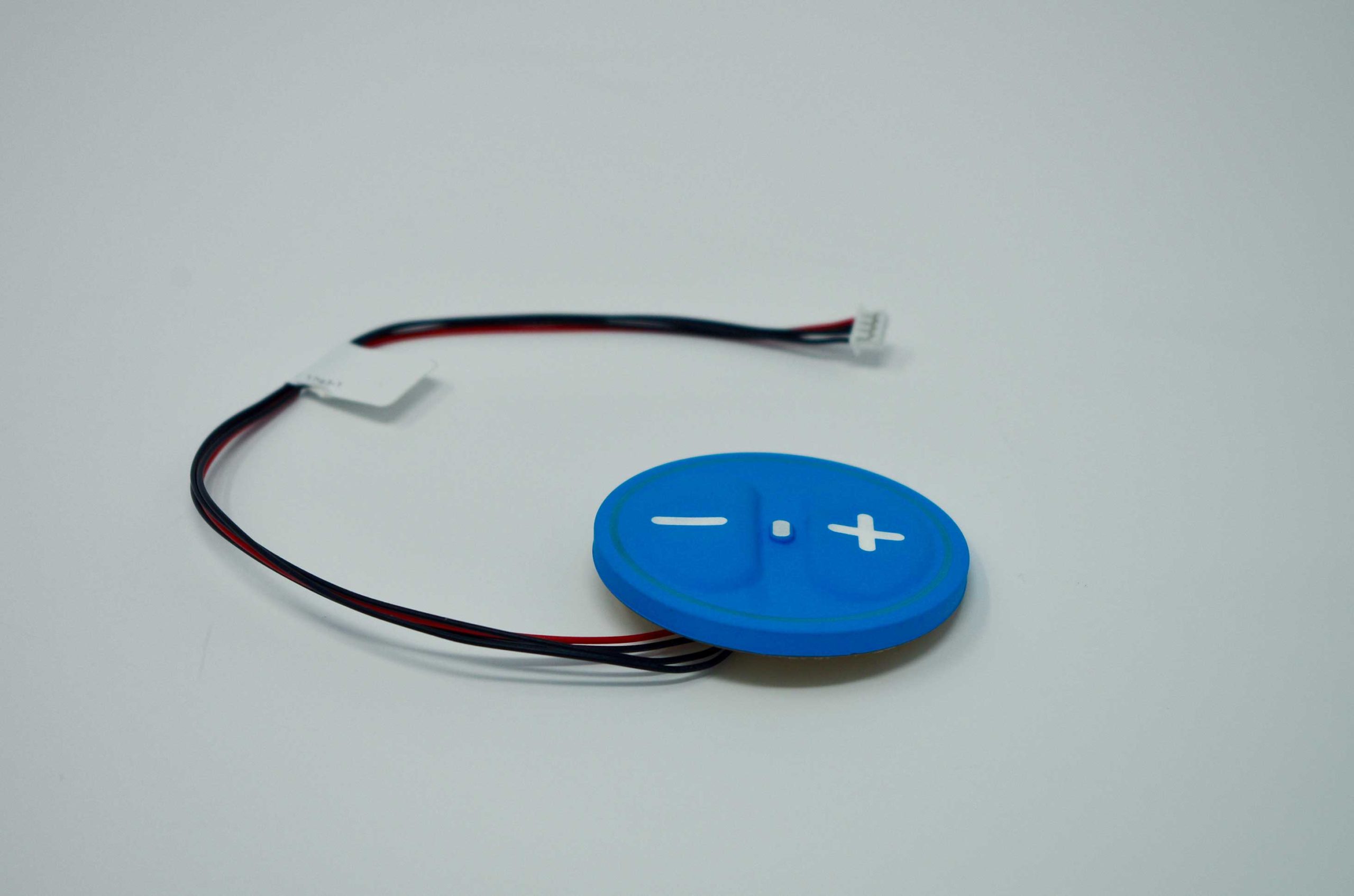

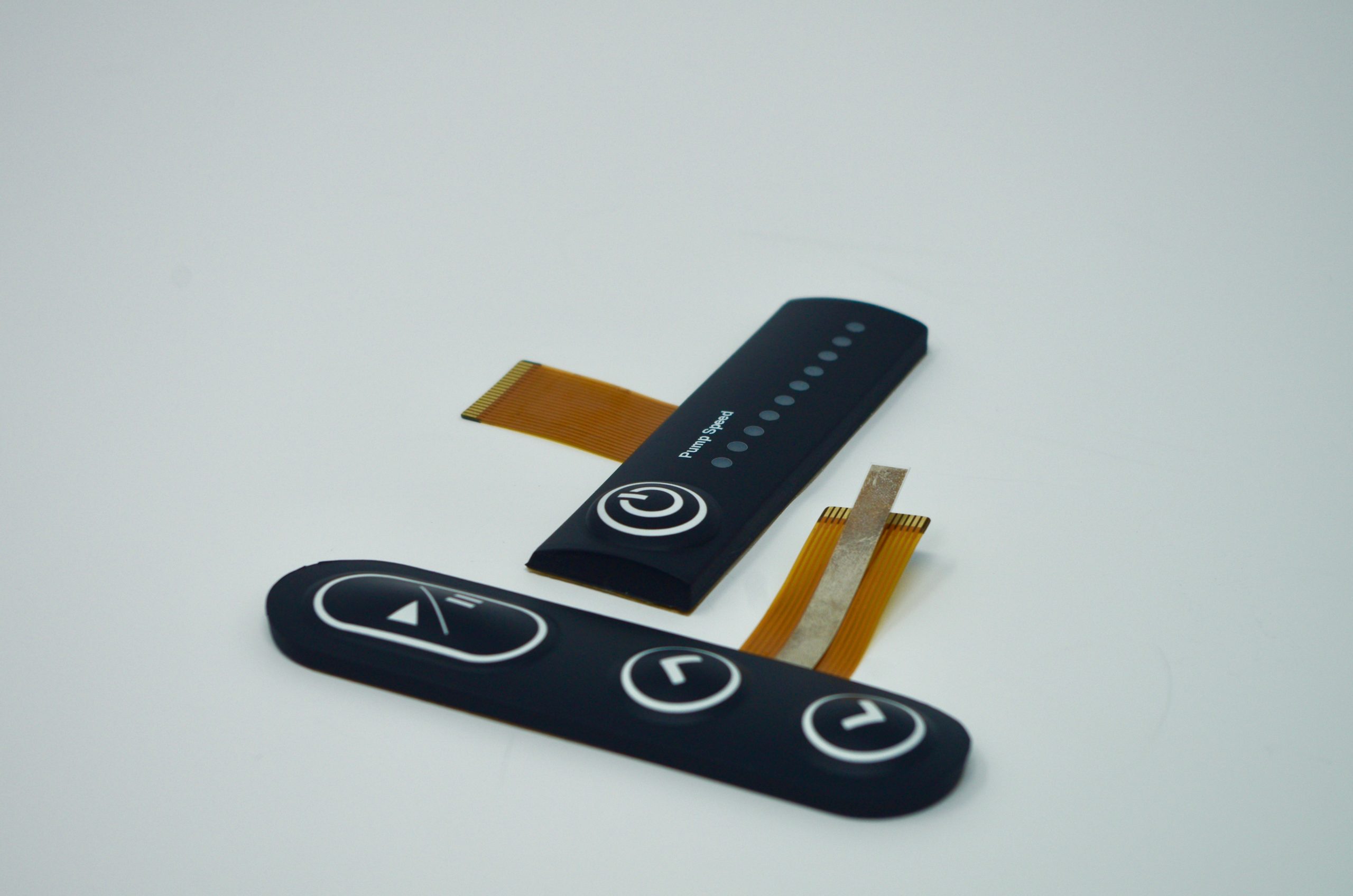

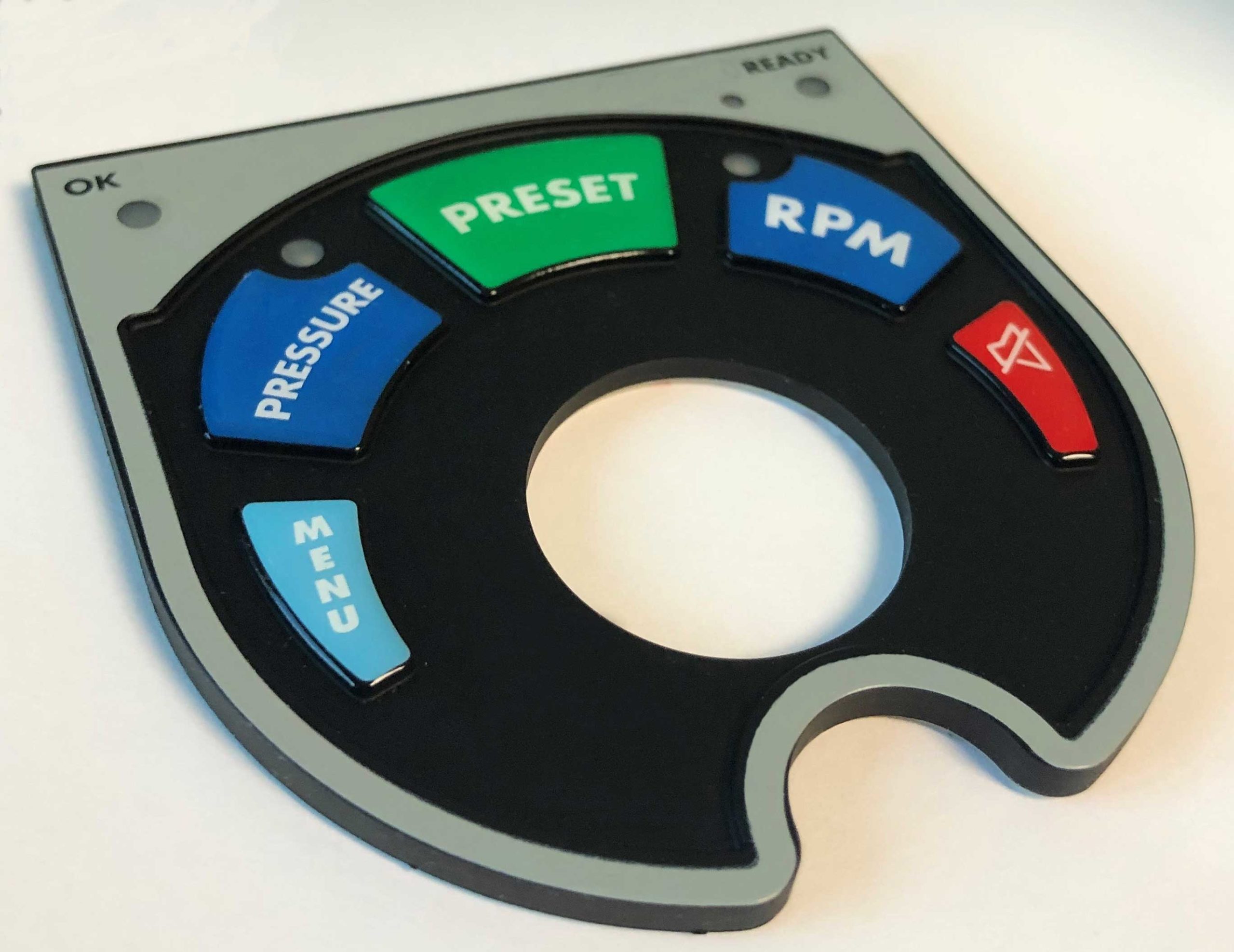

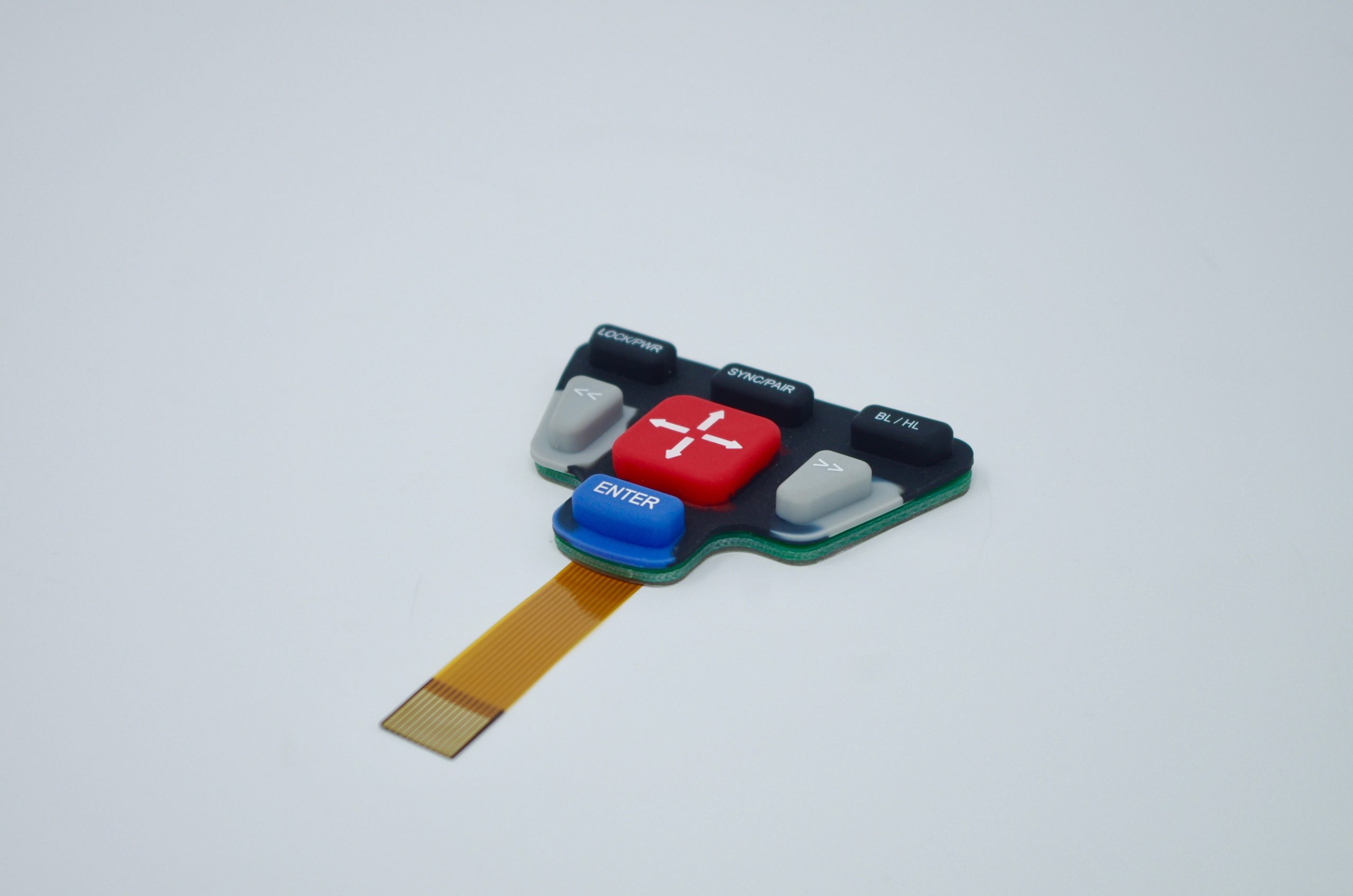

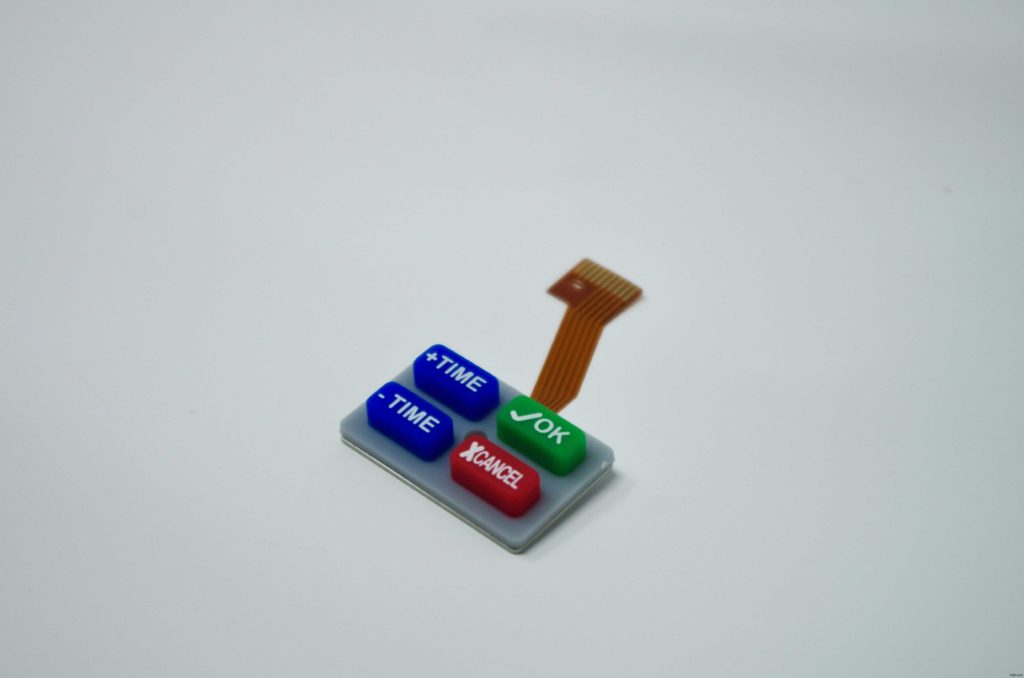

CSI Keyboards is a global leader of custom designed and manufactured elastomer switches and custom silicone rubber keypads. Elastomer switches or rubber keypads are manufactured from silicone rubber properties that are typically processed from either injection or compression molding. Silicone rubber membrane switches use compression-molded silicone rubber (versus polyester or polycarbonate graphic overlay material typically used in standard membrane switch designs) with conductive carbon pills or with non-conductive rubber actuators. They have exceptional resistance to extreme temperatures and environmental factors, making them an ideal choice for products exposed to harsh environmental conditions, moisture, chemicals, etc.

CSI Keyboards is a global leading custom membrane switch manufacturer and custom keypad manufacturer. With our unlimited design and manufacturing capabilities, CSI Keyboards is able to provide our customers with custom tactile membrane keypads and custom keypads that meet their needs as a user interface and face plate to their product. We engineer and manufacture custom membrane switch and membrane keypad technologies that meets specific customer requirements in both performance and visual aesthetics.

- Molding & Decorating Capabilities: Durometer, shape, size and color options

- Key Design: Custom designed actuators and flex walls for optimal performance & tactility

- Circuitry: Copper flex Kapton, printed silver or PCB based

- Switches:

- Metal dome switches

- Conductive carbon pills

- Connection: Rubber keypad connector options

- Backlighting: LED and light piping technology

- Etching: Laser etching capabilities for backlighting

- Coatings:

- PU coatings

- Parylene coatings

- UV resistant coatings

- Environmental sealing: Sealed rubber keypads

- Shielding: EMI / ESD / RFI shielding

- Graphic overlay: Adhesion and integration

- Embossed or debossed molding

- Rubber, plastic, stainless steel keycaps

- Rocker switch and toggle switch panels

- Co-injection elastomeric and plastic molding

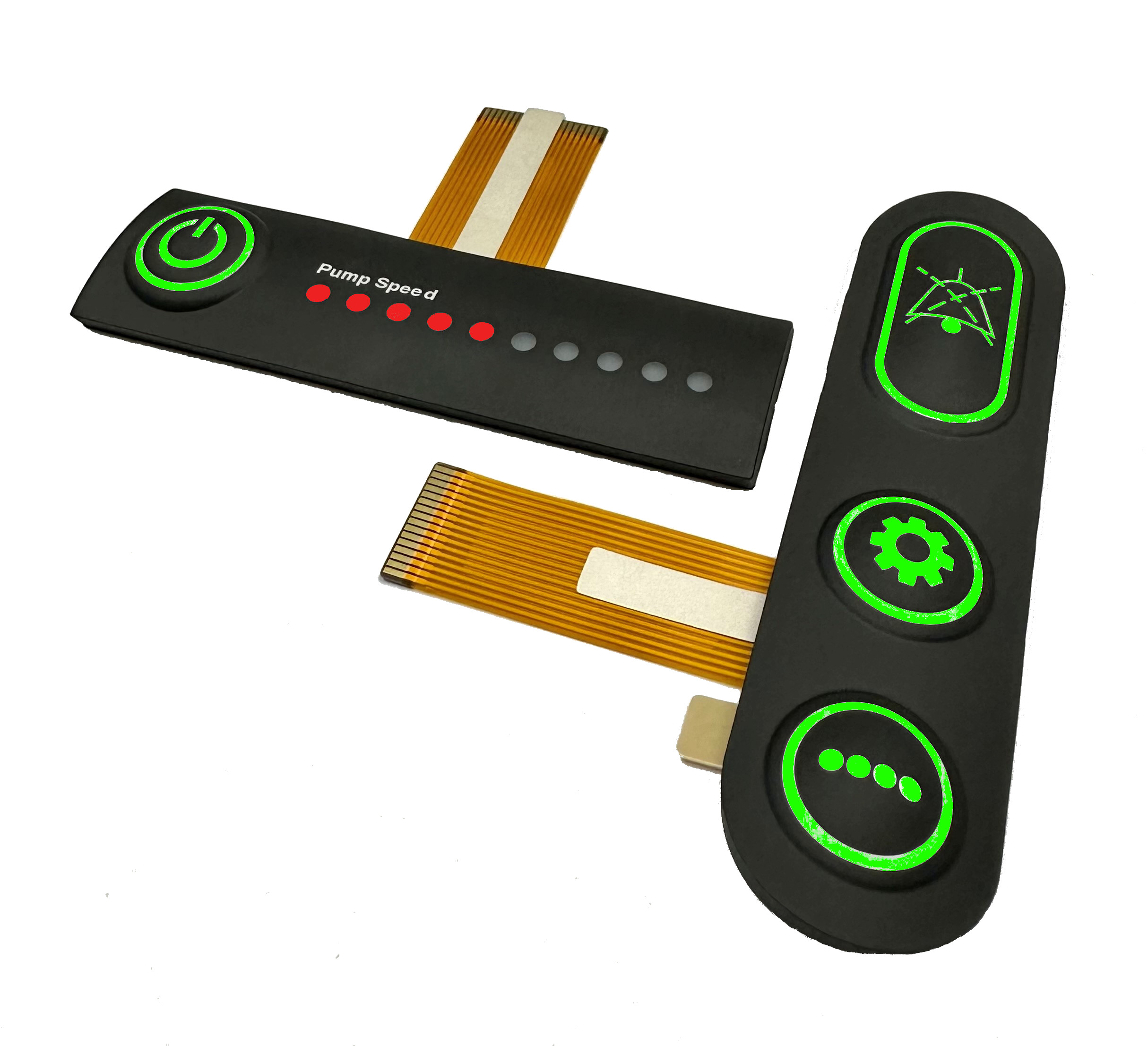

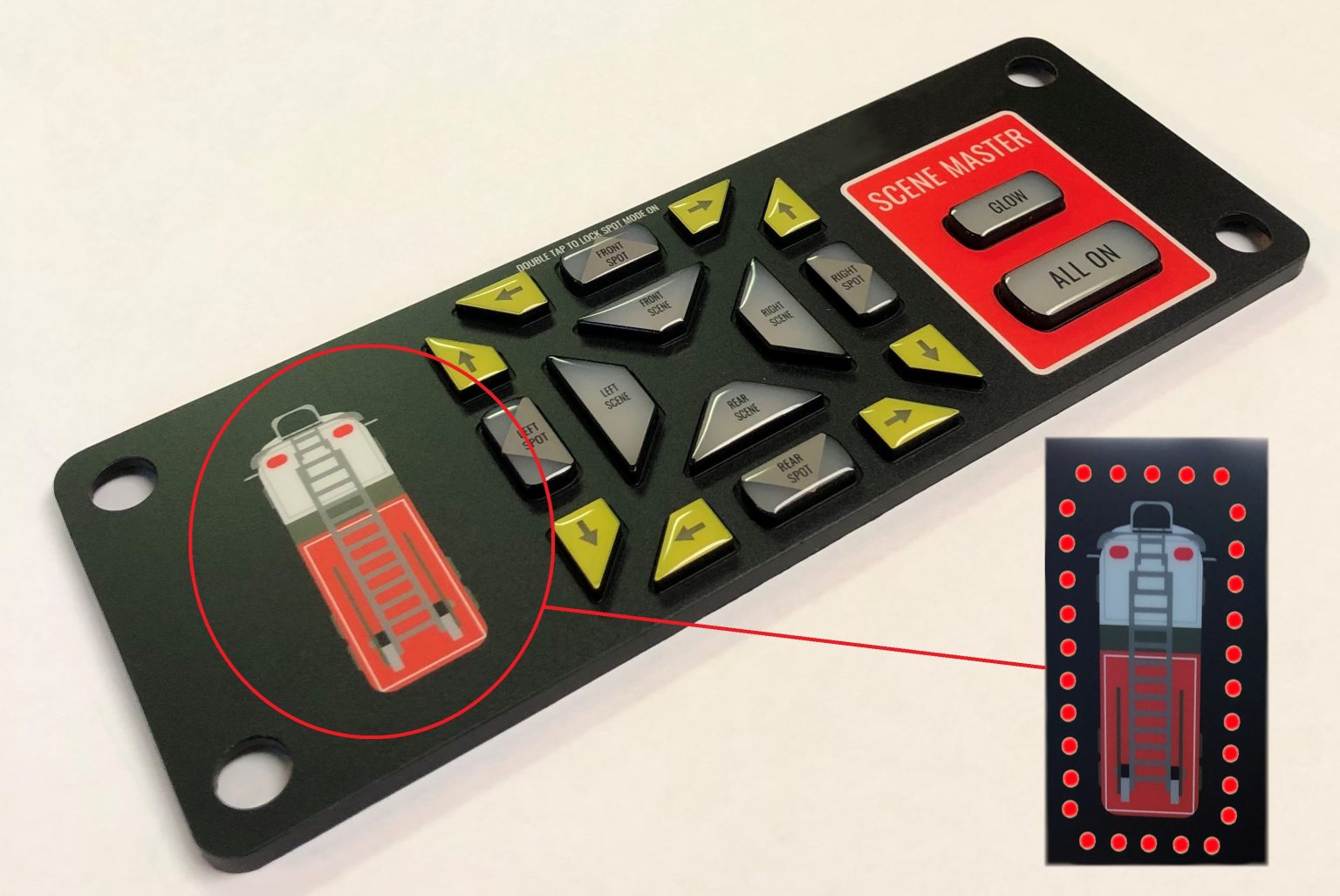

Elastomer Rubber Switch Backlighting

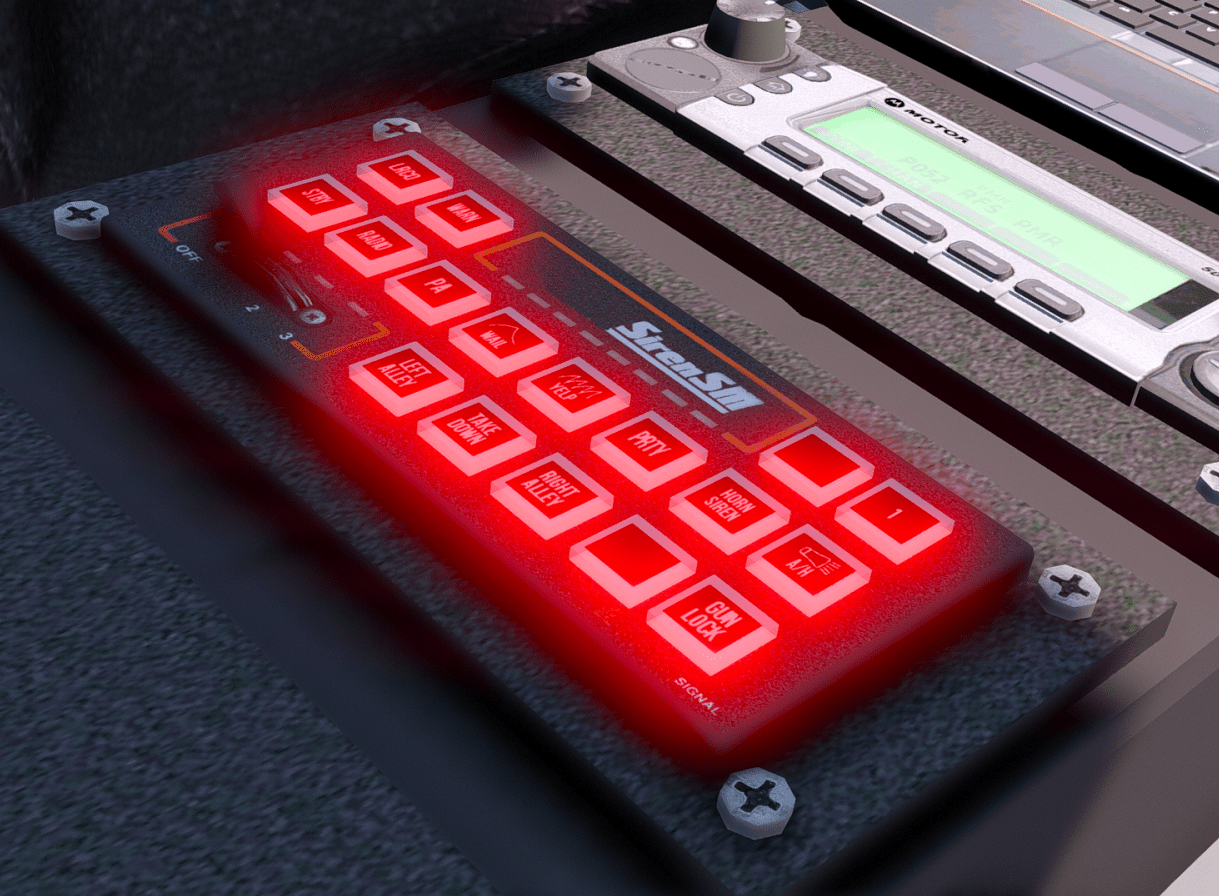

Bring your product to life and really make it “pop” with a backlit rubber keypad solution. When it comes to rubber keypad backlighting, CSI has both the knowledge and expertise to utilize and take advantage of the molded silicone rubber properties which are an excellent conductor of light. CSI Keyboards utilizes laser etching and light piping technology to efficiently backlight rubber keypads to get the very most out of the LEDs and to prevent light bleed or hot spots.

CSI Keyboards has designed and manufactured custom backlit keypad solutions for just about every industry including top tier medical, military, marine, aerospace and industrial industries. CSI will work with you to bring your specific backlit elastomer keypad design to life and make it really stand out from your competition. As a leading rubber keypad manufacturer, CSI Keyboards uses many different technologies to backlight custom rubber keypads including but not limited to:

LEDs

Membrane switches with LEDs are still the most popular and economical method for keyboard backlighting. LEDs are most commonly used to backlight keys, icons and symbols. LEDs are also typically used as indicator lights. A combination of LEDs, Light Guide Film and proprietary CSI backlighting methods can be designed to backlight the entire surface of a user interface.

Light Guide Film (LGF)

Designed to evenly distribute light from top or side firing LEDs, providing bright, uniformed illumination. It also reduces the amount of LEDs needed, saving power consumption. Light guide film dots are also designed and implemented which allow for the optimization of light distribution to obtain maximum brightness and uniformity. Common problems that many of our competitors face are light leakage and hot spots. CSI’s backlighting designs prevent any light leakage and hot spots from occurring, and also result in much brighter light guide film and interface.

Laser Etching

Laser etching refers to a process in which a high powered laser is utilized to remove a layer or layers of paint on a keypad. The molded rubber typically starts off as a translucent, milky-like color and is then painted with opaque colors designed into the part. The rubber is then laser etched down to the translucent layer(s) of the keypad that will eventually be backlit with LEDs. The laser is carefully guided across the surface of the key, burning away paint in select areas. After the paint has been removed, it reveals the translucent layer below. The result is a contrasting translucent and opaque color, making the backlit areas pop with a higher level of crispness, brightness and visibility.

Fiber Optics

Provides a flexible backlighting layer that can be incorporated between the graphic overlay and the circuit layer allowing the entire surface area of the membrane switch to be evenly backlit.

Elastomer Rubber Switch Sealing & Durability

UV Resistant

Environmentally Sealed

Temperature Resistant

Chemical Resistant

Many of our customers require silicone rubber keypads that must be environmentally sealed to withstand harsh environments. Using the most cutting edge silicone rubber switch technology, CSI Keyboards can design a completely sealed silicone keypad product with the use of adhesives and mechanical features to protect both the keypad circuitry, and the electronics that sit behind the custom keypad.

- Rubber Keypad Sealing can be designed into the design of the keypad and our proprietary bonding methods can also be designed in to create NEMA 2, 3 and 4 assemblies. We can design and customize gaskets per your requirements or IP standards which include both IP67 rated keypads and IP68 rated keypads. We have designed sealed rubber switches for marine navigation controls, medical equipment, military applications, industrial controls and food packaging equipment.

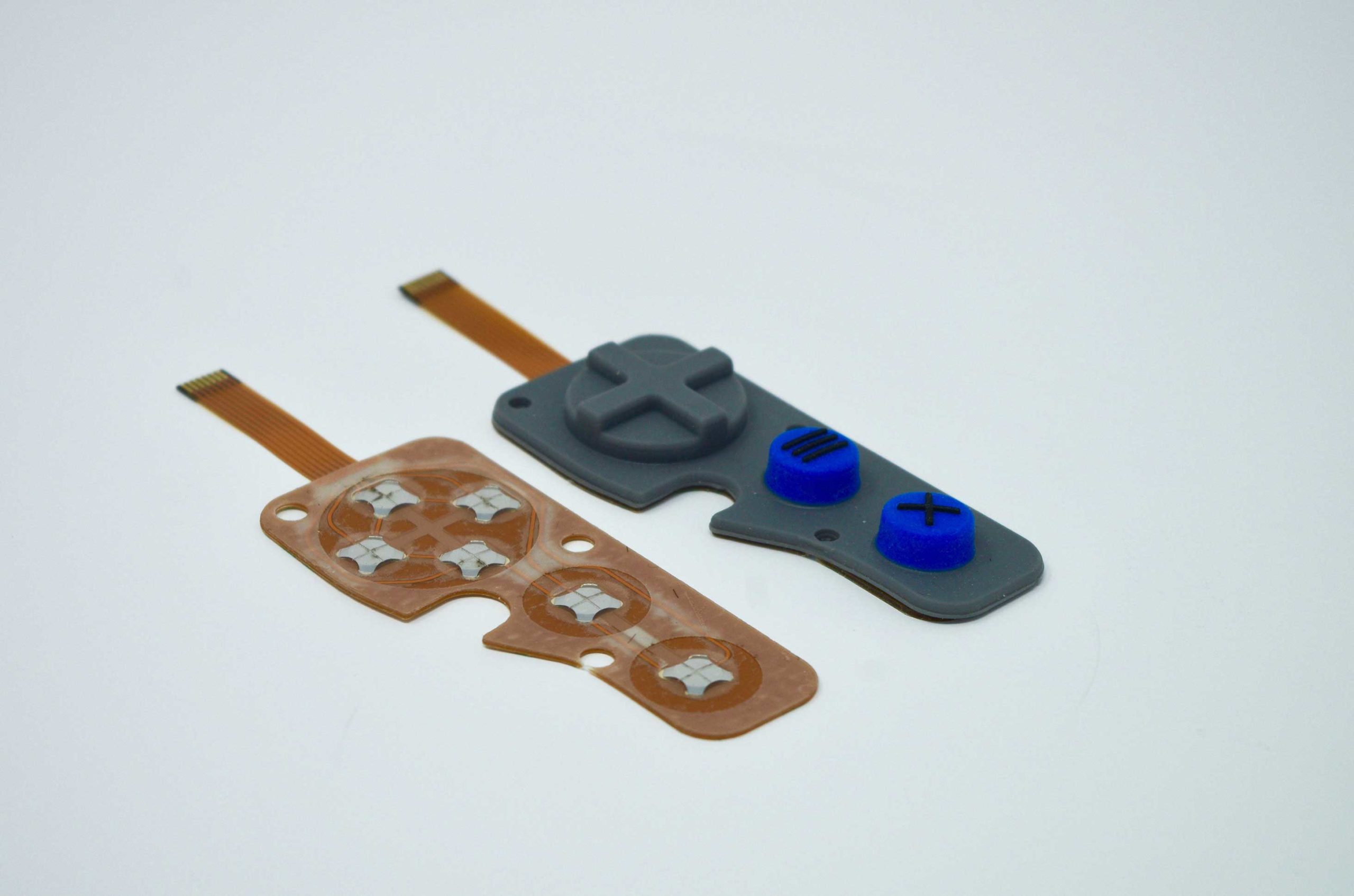

- Copper Flex Rubber Keypads, also known as polyimide Kapton circuitry, are used in the majority of CSI Keyboards’ keypad designs due to its excellent dielectric strength, thermal stability, chemical resistance and flexibility. Copper Flex membrane switch panels are produced using polyimide (Kapton) as the base material. Copper flex switches are manufactured by laminating a thin sheet of copper to a flexible film substrate. The copper is then chemically etched away, leaving the copper traces. An additional layer of polyimide is laminated to the circuit leaving the gold contacts exposed. Copper flex has become the superior choice over printed silver especially for outdoor applications. Copper flex circuitry construction designs offer a significant advantage over printed silver and a printed silver circuit can be replaced with a copper and polyimide construction with minimal additional cost.

- Over Coatings & Finishes are typically applied to our custom silicone rubber keypads to protect your keypad from chemicals, moisture, scratches, and any other wear and tear that the keypad might encounter. We typically use a polyurethane (PU) coating which protects the printed and molded colors on the rubber keypad, and also increases the longevity of the printing and graphics. This coating ensures a longer keypad life regardless of the environment. We also utilize a proprietary coating specially formulated for marine and outdoor applications which provides added protection against UV exposure.

- Seal Frame is a perimeter frame of adhesive that protects your circuitry from any moisture ingress. It have proven to be as robust as other sealing methods such as perimeter temperature sealing and can be included in your design at minimal additional cost.

- Environmentally Resistant Adhesives are utilized in our rubber keypads which are specially formulated to provide high bond strength to any surface. Our adhesives are resistant to humidity, UV, water, temperature, and chemicals.

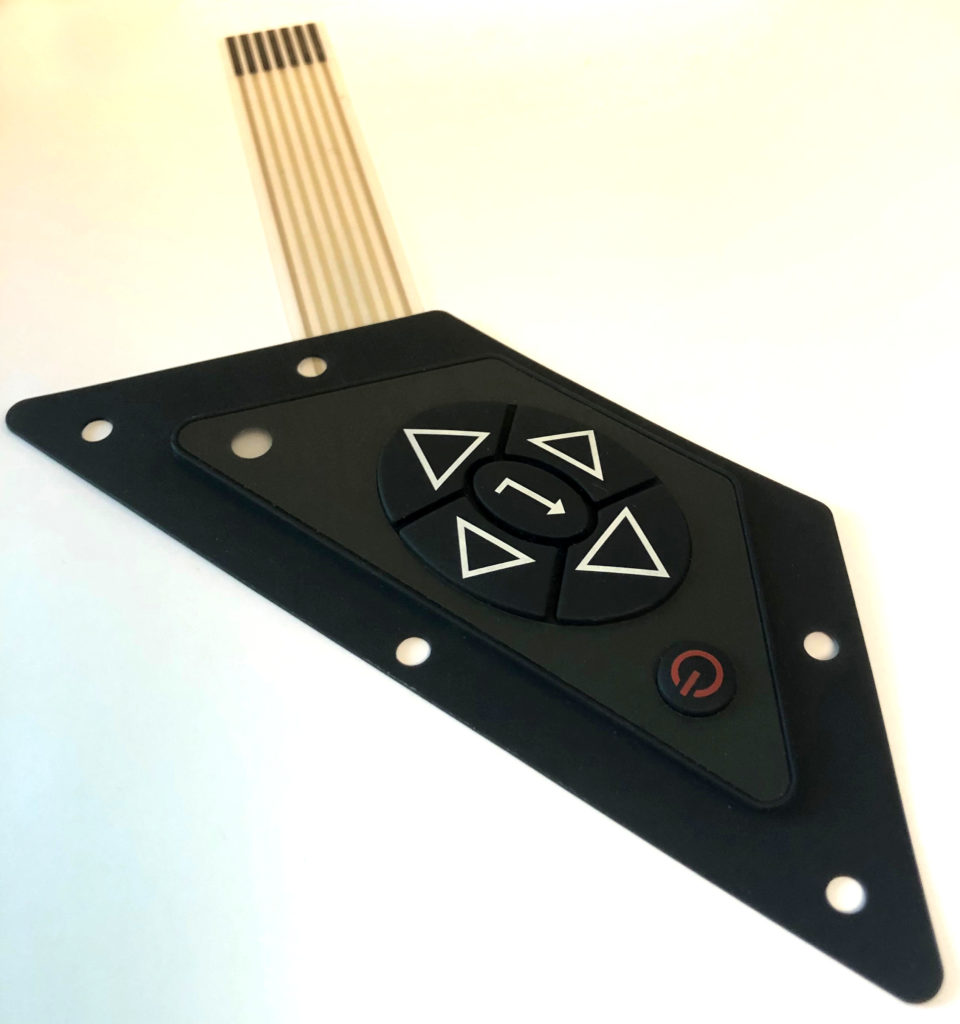

CSI Patented Toggle & Rocker Switches

One of CSI Keyboards’ latest innovations is the patented toggle switch. Utilizing our engineering expertise, we were able to design and engineer a molded silicone rubber rocker switch panel technology that is unmatched in the industry. By perfecting the design of the rubber, the flex wall, the durometer, and dome technology, CSI Keyboards has the only membrane rubber keypad rocker switch on the market.

The only membrane toggle switch on the market is a completely sealed switch that is extremely durable and rugged in design that can easily be integrated into your product. More cost effective and with a longer life expectancy than any mechanical toggle switch available, the toggle switch is an excellent choice for any application. The technology allows for a 2-way, 3-way, or 4-way toggle switch with excellent tactile feel and extremely robust.

Toggle Switch Customization Options:

One of CSI Keyboards’ latest innovations is the patented toggle switch. Utilizing our engineering expertise, we were able to design and engineer a molded silicone rubber rocker switch panel technology that is unmatched in the industry. By perfecting the design of the rubber, the flex wall, the durometer, and dome technology, CSI Keyboards has the only membrane rubber keypad rocker switch on the market.

The only membrane toggle switch on the market is a completely sealed switch that is extremely durable and rugged in design that can easily be integrated into your product. More cost effective and with a longer life expectancy than any mechanical toggle switch available, the toggle switch is an excellent choice for any application. The technology allows for a 2-way, 3-way, or 4-way toggle switch with excellent tactile feel and extremely robust.