Touch Solutions

CSI Keyboards offers both custom touch screens and standard touch screen products utilizing the most cutting edge touch screen technologies available. Each type of touch screen has unique characteristics that can make it the best choice for certain applications.

CSI Keyboards offers tailor made solutions with touch screens integrated with displays into bezels or overlays; membrane and rubber switches; and elastomeric and plastic enclosures. CSI can design and turnkey the entire interface assembly. CSI also offers custom capacitive touch screen, custom resistive touch screen and custom surface acoustic wave touch screen technology in addition to our fully integrated touch screen solutions.

Integrated Touch Screen and Display Solutions

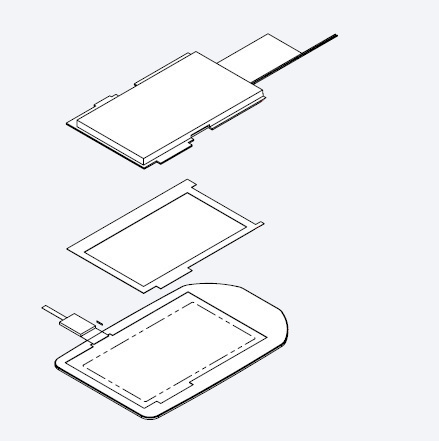

CSI Keyboards’ Integrated Touch Screen and Display Solutions are second to none, combining our many technologies and utilizing our interface expertise to meet your specific product requirements. CSI is able to provide a complete all-in-one, turnkey touch screen assembly incorporating the touch panel, display, and controller integrated into a bezel, open-framed design, panel mount, or keypad. Using optical bonding or adhesive bonding, CSI Keyboards can provide a fully integrated touch screen + display solution to meet your interface requirements. Our touch screen solutions can then be integrated with a graphic overlay, membrane keypad, rubber switch, or bezel for a complete value added assembly. CSI interfaces are carefully designed and built to survive in any environment. Our touch screen solutions can be sealed to prevent moisture and contaminant ingress and are designed to withstand repeated use and chemical cleaning. Applications include medical, POS, industrial, kiosks, military, retail, gaming, office automation, transportation, and commercial.

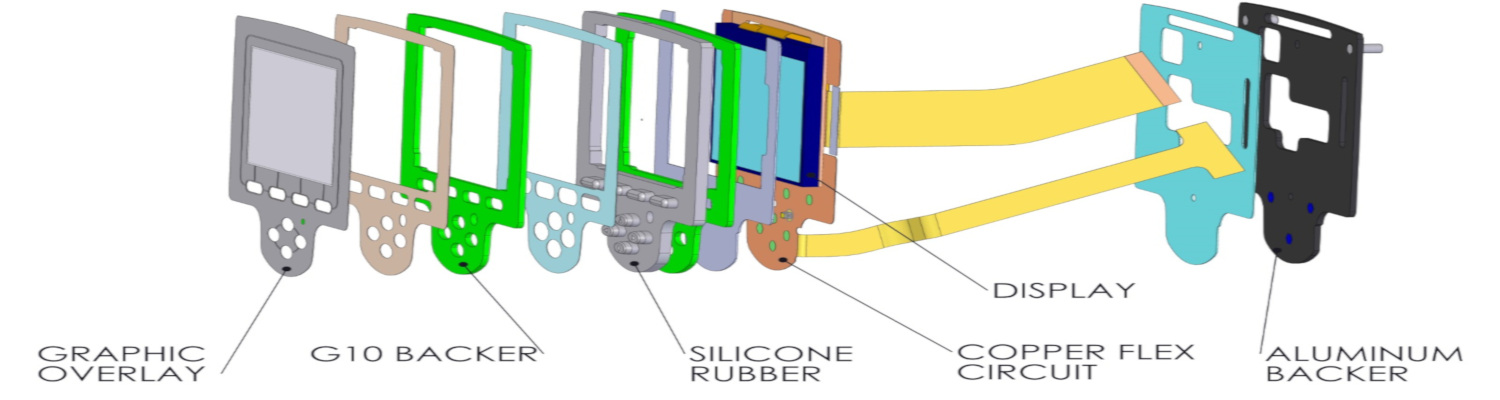

Medical Diagnostics Interface Assembly

The Medical Diagnostics interface was created for rapid and real-time influenza detection. Both its mechanical and electrical design and assembly are tested to meet medical industry standards.

Characteristics:

- Graphic overlay faceplate

- G10 backer for rigidity

- Silicone rubber keys with dome switches

- Display with capacitive touch screen

- Copper flex circuit assembly loaded with electronics

- Metal backer for mounting

- Flex tails exit rear of assembly for connection

Capacitive Touch Screens

Projected Capacitive (PCAP) Touch Screens

The projected capacitive touch screen is essentially a more ruggedized and accurate version of the surface capacitive touch screen. This is made possible by the etching of the conductive material, forming a grid. This grid not only allows for more accurate activation, but also allows for the ITO to be placed behind another layer of reinforced glass for added protection.

CSI’s PCAP touch screen technology delivers precise accuracy with multi-touch functionality required in medical, industrial and consumer industries. CSI offers the below standard projected capacitive touch screens. Any other sizes not listed below can be custom built to meet your requirements at an extremely competitive price. Applications include interactive digital signage, gaming, kiosks, industrial controls, medical equipment, transportation and retail automation.

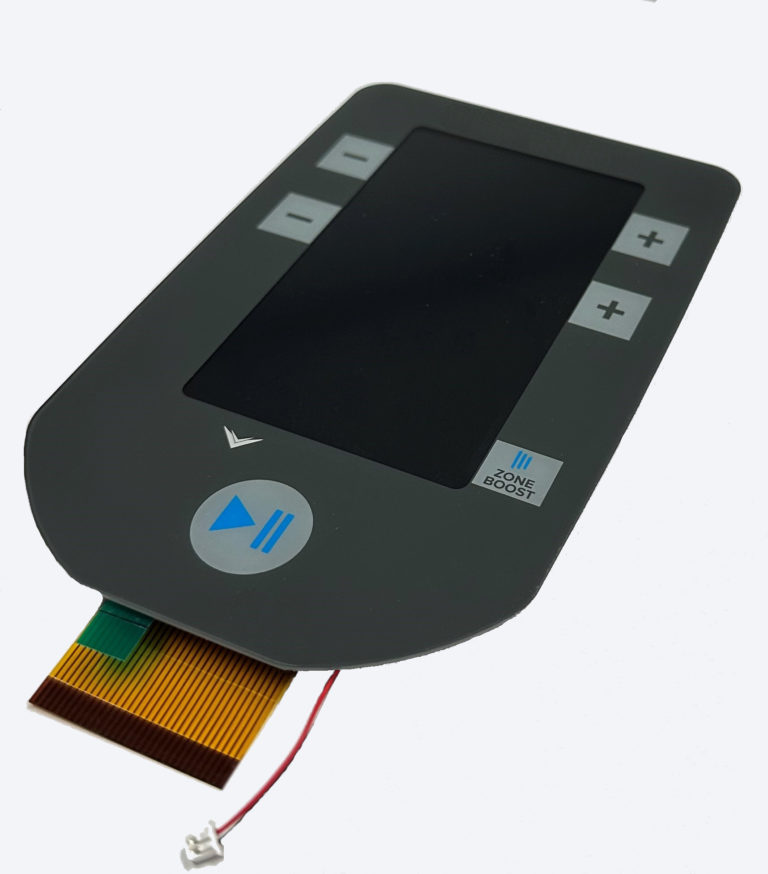

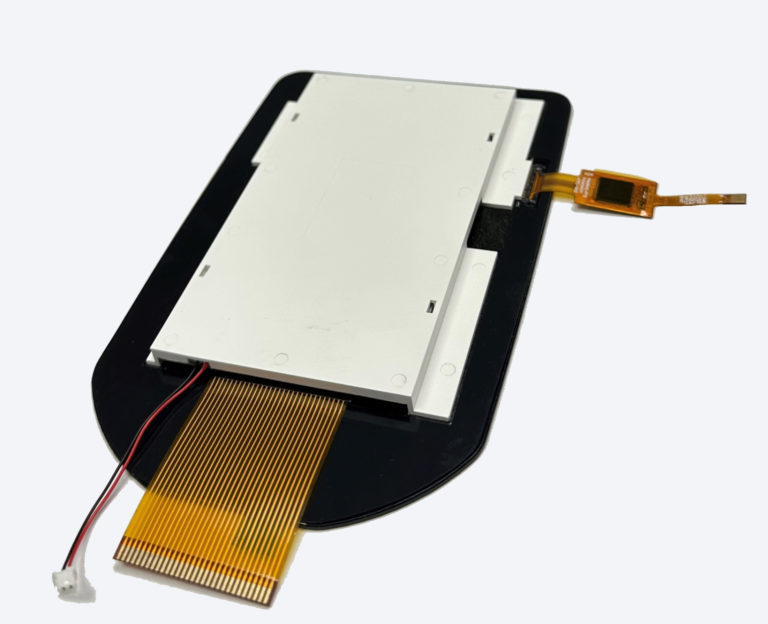

Capacitive Touch Diagnostic Interface

The Capacitive Touch Diagnostic Interface was created for a medical diagnostic product used to take vital signs. Both its mechanical and electrical design and assembly are tested to

meet medical industry standards.

Characteristics:

- Molded rubber with backlit key and icons

- Copper flex circuit with LEDs, components and dome switch

- Capacitive touch + display assembly

- Custom frame backer

Resistive Touch Screens

Resistive touch screen technology consist of transparent and conductive layers separated by a small gap. When an area is pressed, the conductive layers press together and a contact is made. These layers are usually composed of a glass backer, with a conductive coating of ITO on its face, an air gap, and a polyester cover sheet with ITO on the inside, and a clear hard coat on the outside facing the user. When the polyester layer is pressed by the user, the two ITO coatings make contact with one another, and the controller reads it as an activation in a specific part of the grid. Applications include Point-of Sale (POS) Solutions, Industrial Solutions, Medical Solutions and Transportation.

CSI Keyboards offers 4-wire, 5-wire and 8-wire custom resistive touch screen technology.

4-Wire Touch Screen

4-wire touch screens are suited for small to medium sized products, such as PDA and hand-held devices. 4-wire utilizes four edges of the screen presenting X+, X-, Y+ and Y- lead outs. When contact is made, X/Y read-outs are then read by the controller and converted into the correct coordinates.

5-Wire Touch Screen

5-wire touch screens can be produced in screen sizes from 3” to 24”. In the 5-wire touch screen, the top layer is a sense layer while the main circuitry is located in the bottom layer.

8-Wire Touch Screen

8-wire touch screen circuit structure is best suited for screens ranging in size from 6” to 22”. The 8-wire function is similar to 4-wire circuitry but instead has 4 additional screen read-outs. These additional read-outs are used to better adjust possible distortion on the corner or edges of a larger screen.