What are the Differences Between Screen Printing, Digital Printing & Pad Printing?

Screen Printing:

Membrane switches have always utilized screen printing to print circuits and graphic overlays.

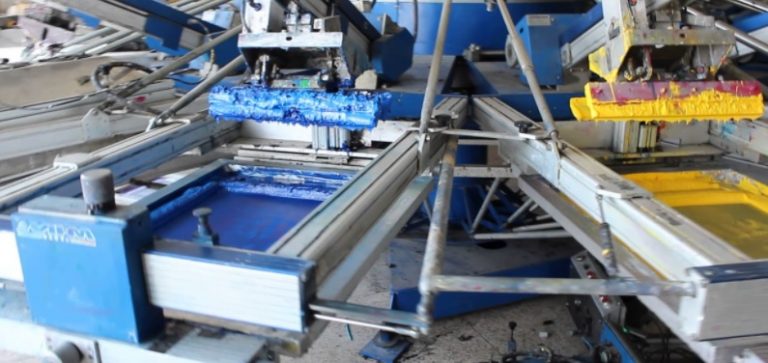

Screen printing is a process that uses a woven mesh stencil to transfer ink to the material underneath or substrate. The stencil contains the actual design or artwork. The screen sits atop the product that will receive the image and a squeegee is moved across the screen to fill the open mesh apertures with the ink to create the design on the substrate.

The process was known as silkscreening because silk was originally used as the material. Nowadays, synthetic materials are used in the screen printing process typically polyester, nylon, or stainless steel materials.

Digital Printing:

Digital printing is the process of sending information from a device, typically a computer, to the printer using digital files created by graphics software. The information is reduced to binary code for storage and reproduction.

Digital printing is ideal for membrane switch designs that are more complex than the traditional artworks such as 3D graphics, textures, fading, half-tones and other effects that cannot be screen printed.

Pad Printing:

Pad printing is a process that transfers a 2D image onto a 3D object. Pad printing is typically used to print images on to more difficult products or surfaces. It involves three main components: an etched plate, a silicone pad to transfer the image, and the substrate. An image is etched into the flat printing plate which is then filled with ink. The silicone pad has a very smooth surface with chemical resistances which is then used to carry the ink from the plate and transfer it onto the object. The silicone material is ideal because it does not absorb the ink and can adapt to irregular shaped surfaces.