What is a Dome Switch Keypad?

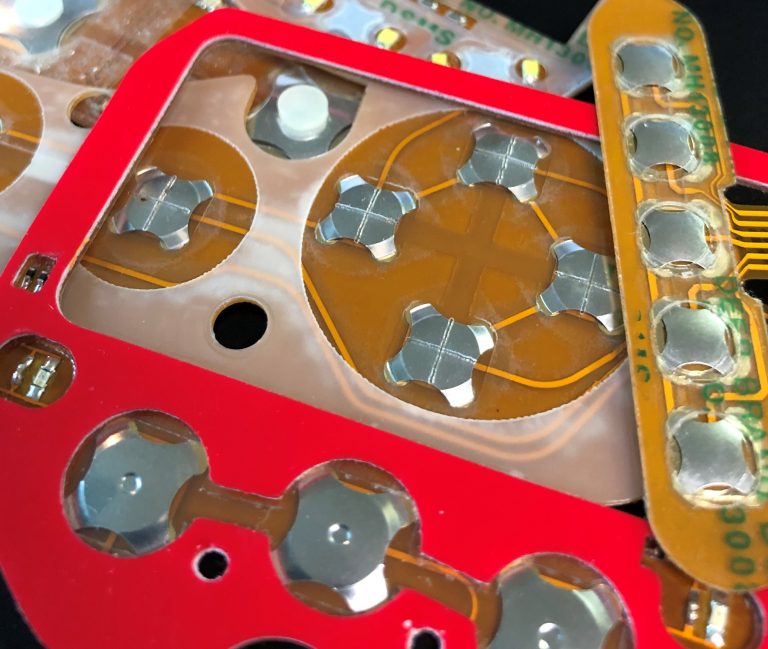

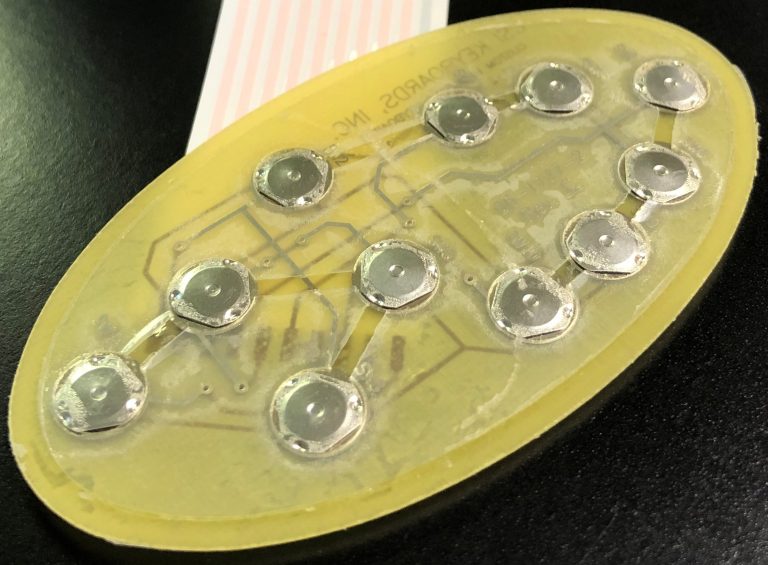

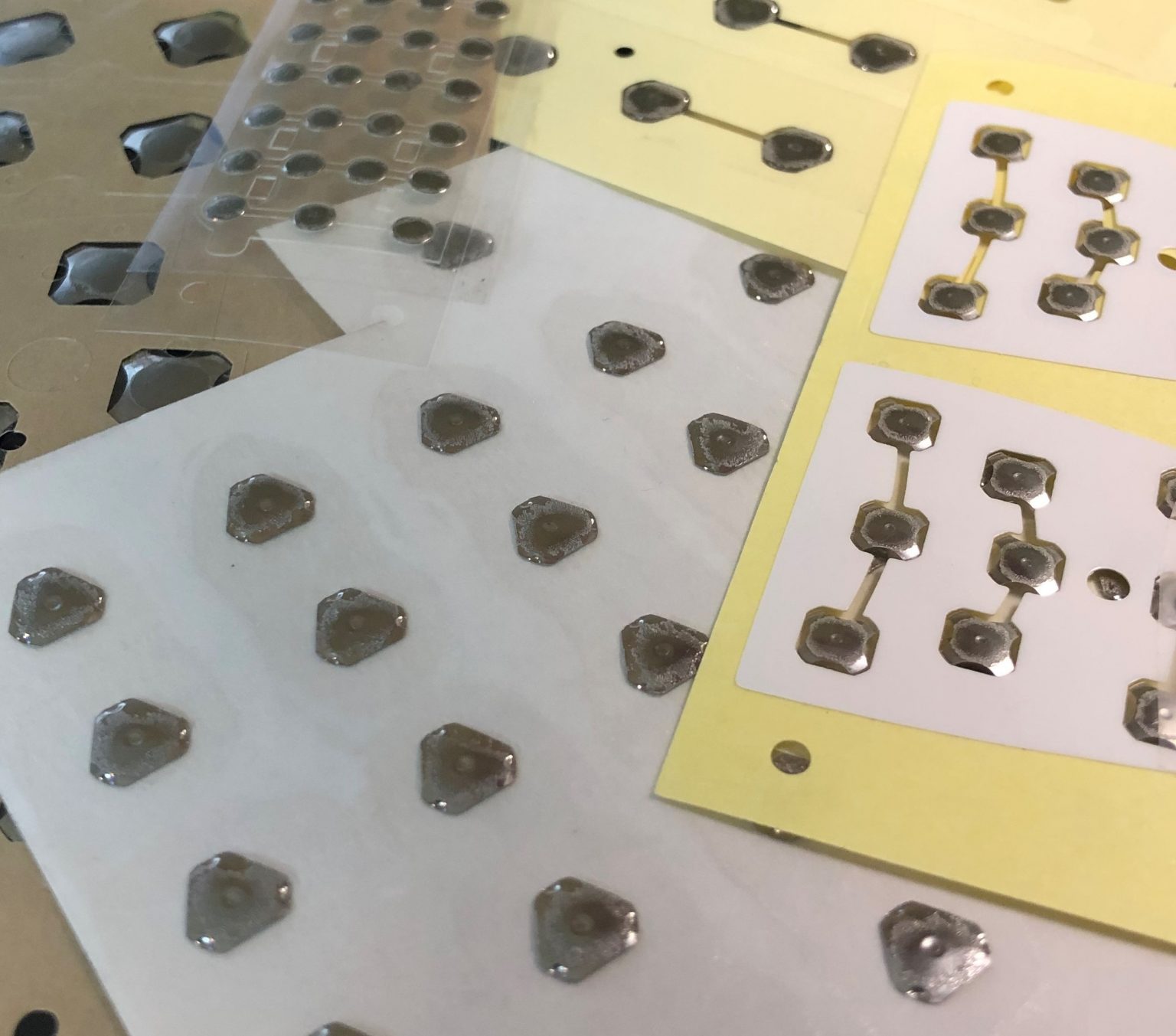

CSI Keyboards designs domes into the majority of our membrane switches. Dome switch keypads use two circuit board traces in conjunction with a metal dome. Metal domes, which are typically made of stainless steel, are momentary switch contacts that provide tactility or “snap” when pressed. The domes become normally-open tactile switches when actuated on the circuit.

The main advantage of dome switch keyboards is the tactile snap or feedback when actuated. When pressing the key, the user realizes they have actually actuated or successfully pressed the switch due to the feel and sound feedback received from the dome.

Another major benefit of the dome switches are the the long lifespan and reliability. Standard dome switch keypads are now rated from one million to even five million cycles. They are still the most reliable type of switch available in the membrane switch space.

Dome Options:

- Dome plating: can be plated in other metals such as nickel, silver or gold

- Dome shapes: four legged, triangle, round, oblong

- Dome sizes: standard sizes are 6mm, 7mm, 8.5mm, 10mm, 12mm, 14mm, 16mm

- Dome forces: standard forces range from 85g to 700g

- Other options: dimpled, hole in center (for backlighting key), double-contact closure domes.

Actuation force is the amount of force required to make the dome snap. Or in other words, how much force is required to change the dome from the open position to the closed position. Dome actuation force is typically measured in grams.

How Do I Choose the Right Dome for my Membrane Switch?

The CSI engineers will work very closely with you in deciding which dome is best for your application. Typically the decision is based on the force of the dome (how soft or hard of a press it takes to actuate the dome) and is extremely subjective. CSI can mock up different sample keypads with different dome options so the customer can decide through a more “hands-on” approach.