About CSI Keyboards

History

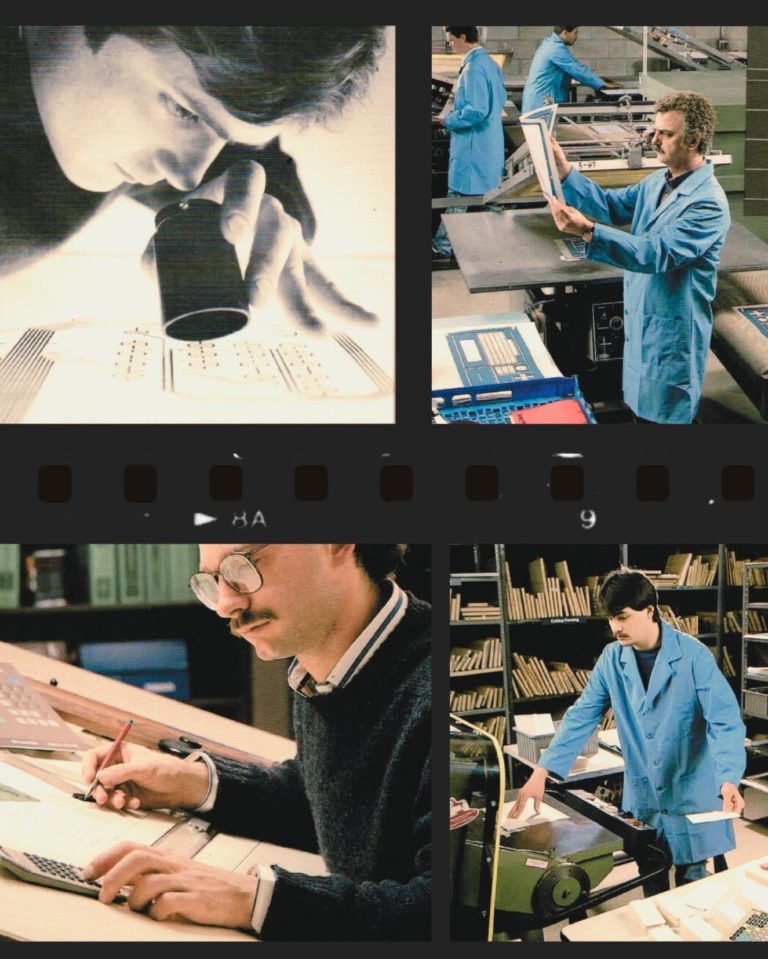

CSI Keyboards has been a global leading manufacturer of membrane switches and human machine interface technologies for over 40 years. CSI was founded in 1982 in Salem, Massachusetts specializing in the design and manufacturing of membrane keyboards, membrane switches and keypads. Outgrowing the Salem location only a couple of years later, CSI relocated to a larger facility in Peabody, Massachusetts, where the company still operates, expanding and upgrading both its manufacturing and front office space.

CSI is continually expanding and diversifying its products and capabilities, offering the most cutting edge and innovative user interfaces and HMI solutions including: membrane switches, elastomer silicone rubber keypads, touch screen solutions and display assemblies, capacitive switches and full turnkey HMI solutions

CSI has been a trusted value-added partner in leading-edge technological solutions for medical, military, industrial controls, marine, aerospace, commercial and military customers. Specializing in the design, engineering and manufacturing of user interfaces, CSI offers a full range of HMI products and solutions that can be customized to meet your specific requirements.

Why Our Customers Choose CSI

Experience

40+ years

3500+ custom HMI products

150+ designs per year

Speed & Efficiency

Concept to Design: ≤ 2 weeks

Design to Part: 4-5 weeks

Rapid Prototyping: 2-3 weeks

Engineering

Experienced engineering specialists solely focused on keypad and user interface designs

Local Support

Local Sales, Product Management, Engineering, and Quality Support

On-Site Manufacturing, Assembly, Quality, Shipping Teams: ensures parts are built, tested, and shipped to conform to the highest standards

Overseas Manufacturing

Utilized for larger production volumes and to ensure we can offer the most competitive pricing to our customers

Design & Engineering Expertise

As one of the most experienced keyboard manufacturers and membrane switch companies in the country, CSI Keyboards boasts an unmatched engineering team in the membrane keypad industry having well over 100 years of combined experience. CSI’s engineering team has designed and engineered highly durable and reliable membrane keypads, rubber switches, and other user interfaces for top tier medical, military, industrial, aerospace, marine, food equipment, automotive fitness, and appliance companies all over the world.

While the majority of our competitors rely solely on overseas engineering and manufacturing sources, CSI Keyboards’ engineering department is based here at our ISO 9001: 2015 certified facility in Peabody, MA, USA making communication with our customers seamless from the early stages of the design, right through final production, and then throughout the life of the product. Having the ability to both design and assemble custom membrane keyboards and human machine interfaces in-house also gives our engineers unmatched rapid prototyping capabilities that other keypad manufacturers simply cannot offer.

Our user interface engineers have developed some of the most innovative designs ever to be introduced to the membrane keypad and switch industry including new cutting-edge methods of backlighting, environmentally sealing and ruggedizing keypads to withstand the harshest of conditions.

Manufacturing

As one of the most experienced keyboard manufacturers and membrane switch companies in the country, CSI Keyboards boasts an unmatched engineering team in the membrane keypad industry having well over 100 years of combined experience. CSI’s engineering team has designed and engineered highly durable and reliable membrane keypads, rubber switches, and other user interfaces for top tier medical, military, industrial, aerospace, marine, food equipment, automotive fitness, and appliance companies all over the world.

While the majority of our competitors rely solely on overseas engineering and manufacturing sources, CSI Keyboards’ engineering department is based here at our ISO 9001: 2015 certified facility in Peabody, MA, USA making communication with our customers seamless from the early stages of the design, right through final production, and then throughout the life of the product. Having the ability to both design and assemble custom membrane keyboards and human machine interfaces in-house also gives our engineers unmatched rapid prototyping capabilities that other keypad manufacturers simply cannot offer.

Our user interface engineers have developed some of the most innovative designs ever to be introduced to the membrane keypad and switch industry including new cutting-edge methods of backlighting, environmentally sealing and ruggedizing keypads to withstand the harshest of conditions.

Quality

CSI’s quality department has developed a quality structure to drive continuous improvement, striving to constantly improve our quality across all facets of our business, including: design and engineering, sales and customer service, throughput, and manufacturing.

Each employee at CSI Keyboards is personally committed to doing whatever it takes to produce quality products that are delivered on-time. As a leading keypad manufacturer, CSI employees takes an active role in ensuring that the parts we design, manufacture, assemble and produce are of the highest quality.

Testing is a critical part of our manufacturing process, hence all of our products are tested 100% both electrically and cosmetically before they are carefully packaged and shipped to our customers.

ISO 9001: 2015 Certified

As our further commitment to quality, CSI Keyboards, Inc. is ISO 9001: 2015 certified. ISO 9000 is a series of quality management systems standards created by the International Organization for Standardization (ISO), a federation of 162 member countries based in Geneva, Switzerland. The American National Standards Institute (ANSI) is the member body representing the United States. ISO 9001:2015 is a comprehensive Standard in the ISO series, covering design, manufacturing and, most importantly, customer focus. The ISO 9001: 2015 certification is a testament to CSI Keyboards’ continued commitment to quality and service in the design and manufacturing of membrane keypads and user interfaces.

The Process

Collaborate & Design

The process starts by collaborating with the customer and can startwith something as simple as adescription or sketch.

Prototype

Once we have designed the product and received customer approval, we begin the prototyping process.

Production

After prototypes are approved, we enter the product into full scale production.

Sustainability

Sustaining and supporting the userinterface throughout the life of the product. CSI is still supporting products that wereoriginally designed 40 years ago.