Electroluminescent (EL) Panels Explained

EL or Electroluminescence is one of many technologies used to uniformly backlight overlays or membrane keypads. EL is applied on a very thin layer between the graphic overlay and the circuit. EL uses a printable ink deposit to illuminate the switch and provide a uniformed illumination.

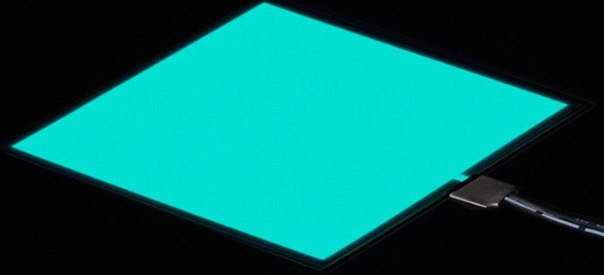

EL panels are the big brother to EL wires – it has the same glow effect but with a flat shape instead of a round shape. The panel is a large sheet of flexible plastic coated with EL material so it’s like one large glowing square. The EL panel emits an even and uniformed glow over the entire shape.

You can attach the panel by adhered it to the back of a flat surface. It is flexible but will crease and damage if folded. You can cut the panel up as long as the shape you cut out is continuous and has the cable attached. This panel is a blue-green/aqua color when lit and is the brightest of the panels as it is the natural color of EL panel.

Like all EL products, an inverter is required to operate the panel. Because EL tape has more surface area than wire, it requires a more powerful inverter. We suggest you use our 4 x AAA inverter which is strong enough to power a single panel at once. For more permanent installations, the 12V EL inverter can also power a single panel and run off 8 x AA batteries or a wall adapter.