What are Metal Domes and How Do I Choose the Right One?

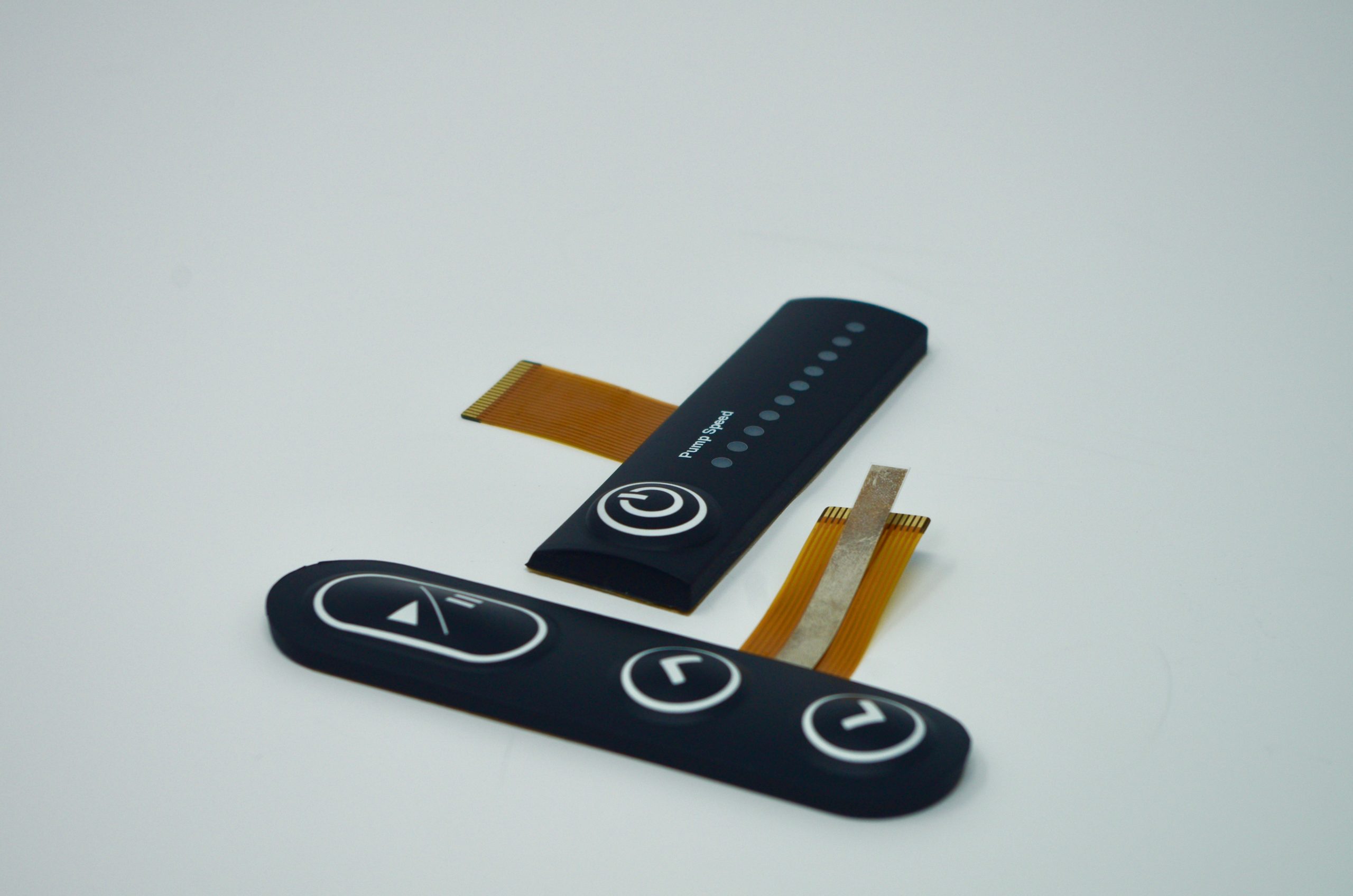

What are metal domes and how do I choose the right one for my membrane switch? This is one of the most common questions that is raised by our customers during the design process.

So what is a metal dome?

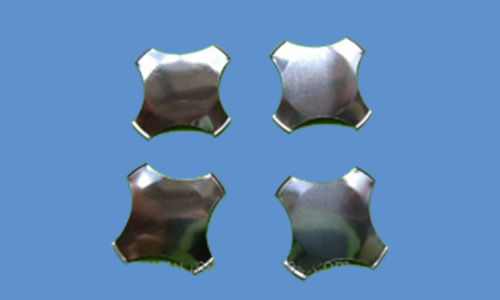

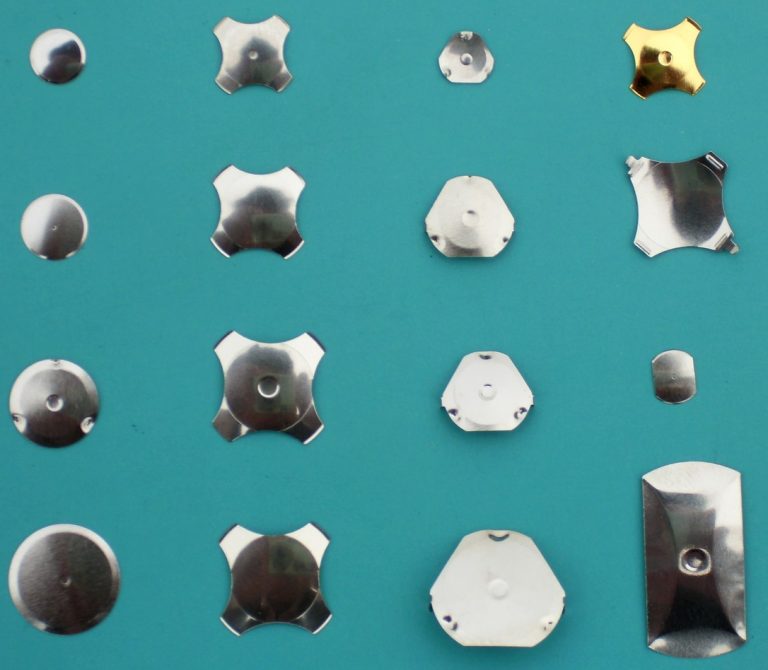

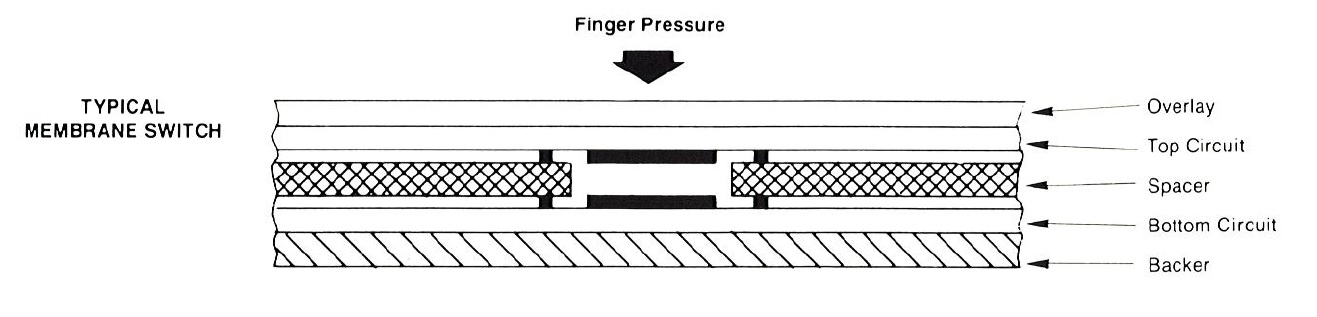

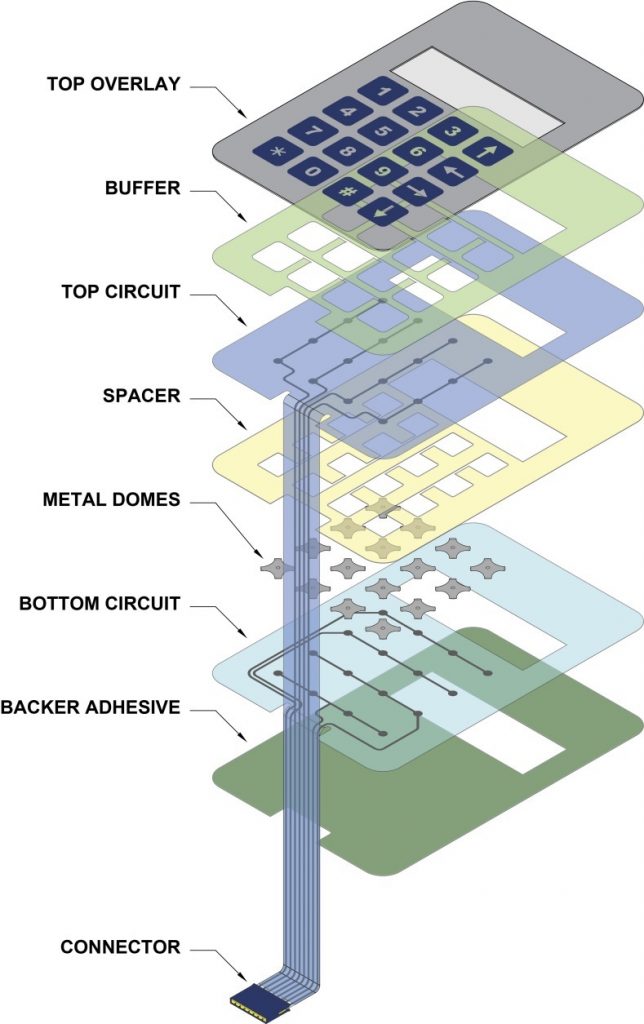

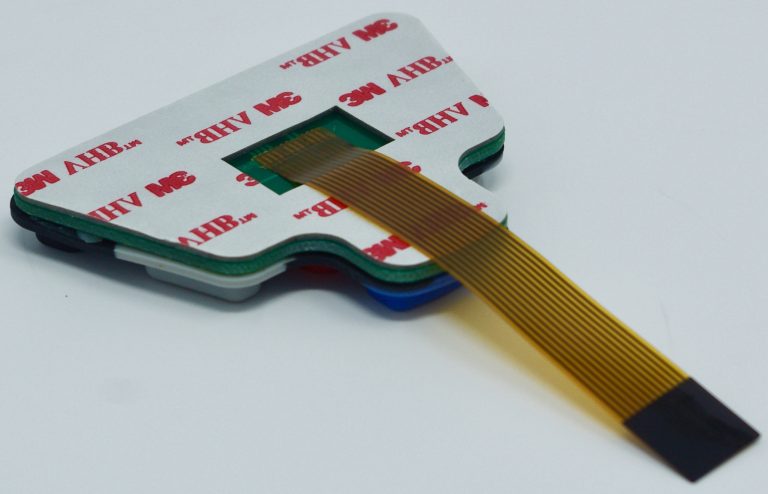

Metal domes (metal snap domes, or tactile metal domes), made of stainless steel, are momentary switch contacts that, when used in conjunction with a PCB, flex circuit, or membrane, become normally-open tactile switches. All of the domes that CSI designs into our products are rated for at least one million cycles.

Domes typically come in the following shapes:

- Four legged

- Triangle

- Round

- Oblong

- Custom

How do I choose the right one?

The CSI engineers will work very closely with you in deciding which dome is best for your application. Typically the decision is based on the force of the dome (how soft or hard of a press it takes to actuate the dome). CSI can also mock up different sample keypads with different dome options so the customer can decide through a more “hands-on” approach.