Environmentally Sealed Switch

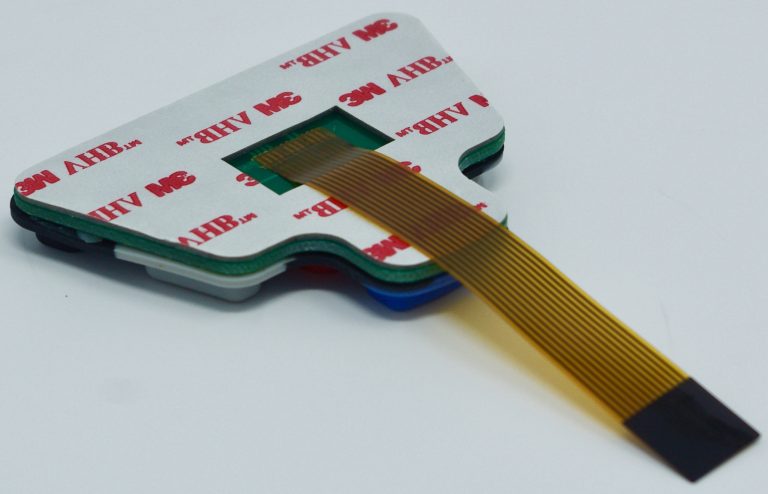

CSI Keyboards was asked by our customer to design an environmentally sealed switch with backlight assembly that would withstand the destructive temperatures of the arctic as well as the dry heat of the desert without these extremes degrading its functionality. The reliability of these switches was paramount as they were to be used as lighting controls for temporary military field housing.

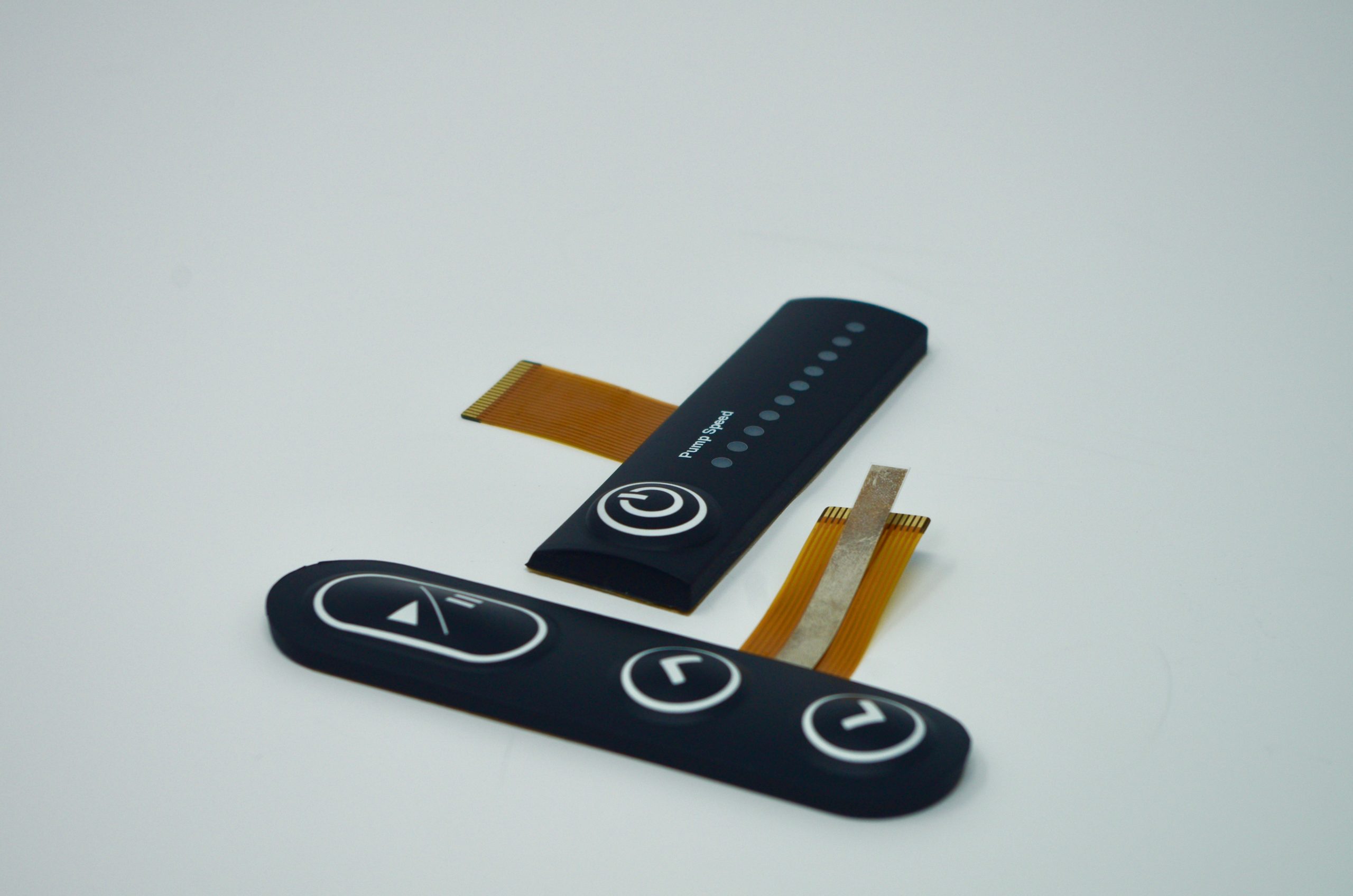

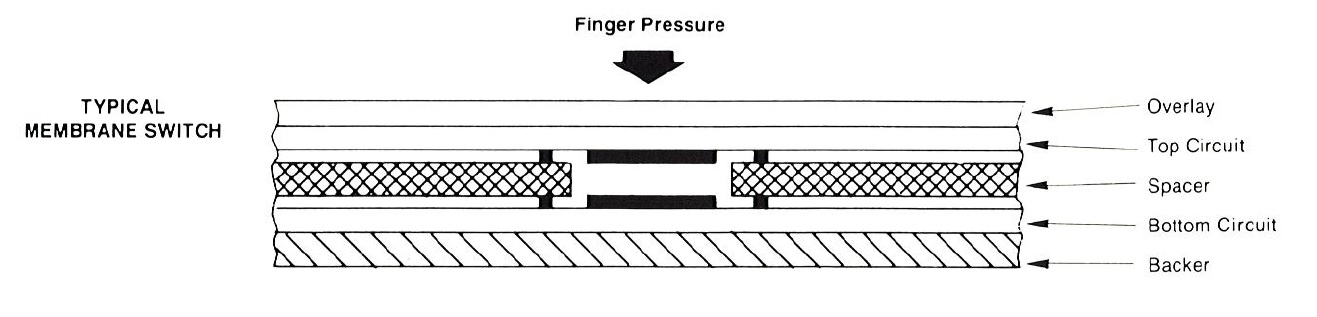

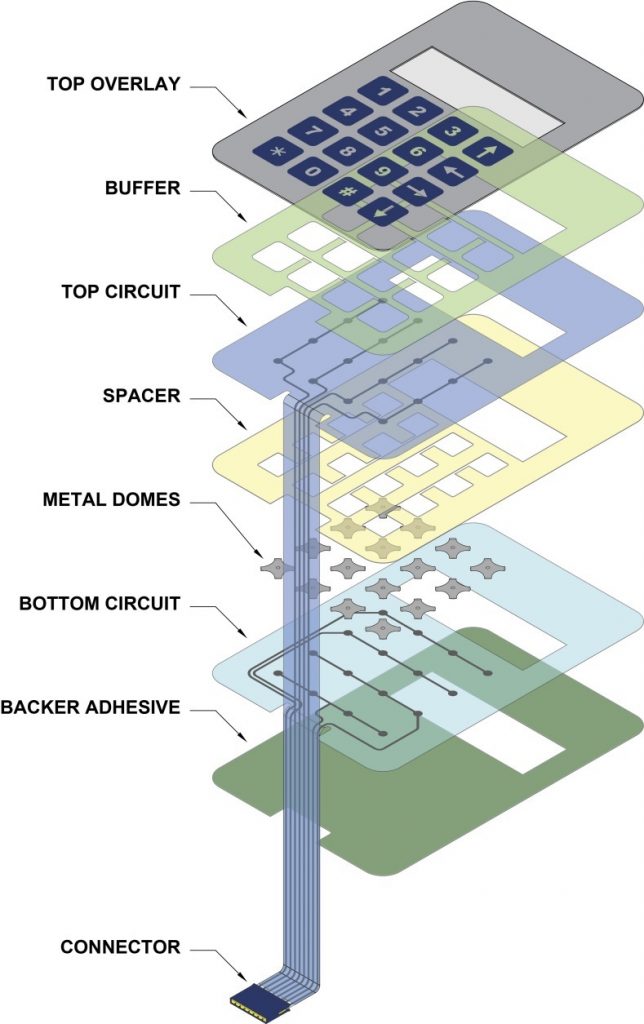

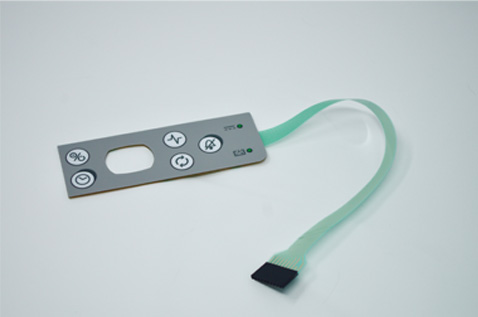

CSI recommended an assembly consisting of a silicon rubber keypad, a Kapton etched circuit, and silicone adhesive based on the bullet points below:

· Silicone rubber is extremely durable and performs well in all temperatures.

· Etched copper circuitry on Kapton film is a more durable material than silver ink on

polyester, able to withstand moisture and extreme temperatures.

· Silicone adhesive is extremely durable and reliable regardless of extreme temperatures

or wet environments.

After approval of the proposed design, CSI produced first articles for test and qualification. These were tested to expanded temperature standards and have been qualified from +150 C down to -50 C. After test and qualification our customer went into production with our design. Over the first 2 years of production they have experienced zero field failures. If your application needs to be reliable and stable in extreme temperatures, CSI Keyboards is the supplier to partner with.