Flexible Circuits

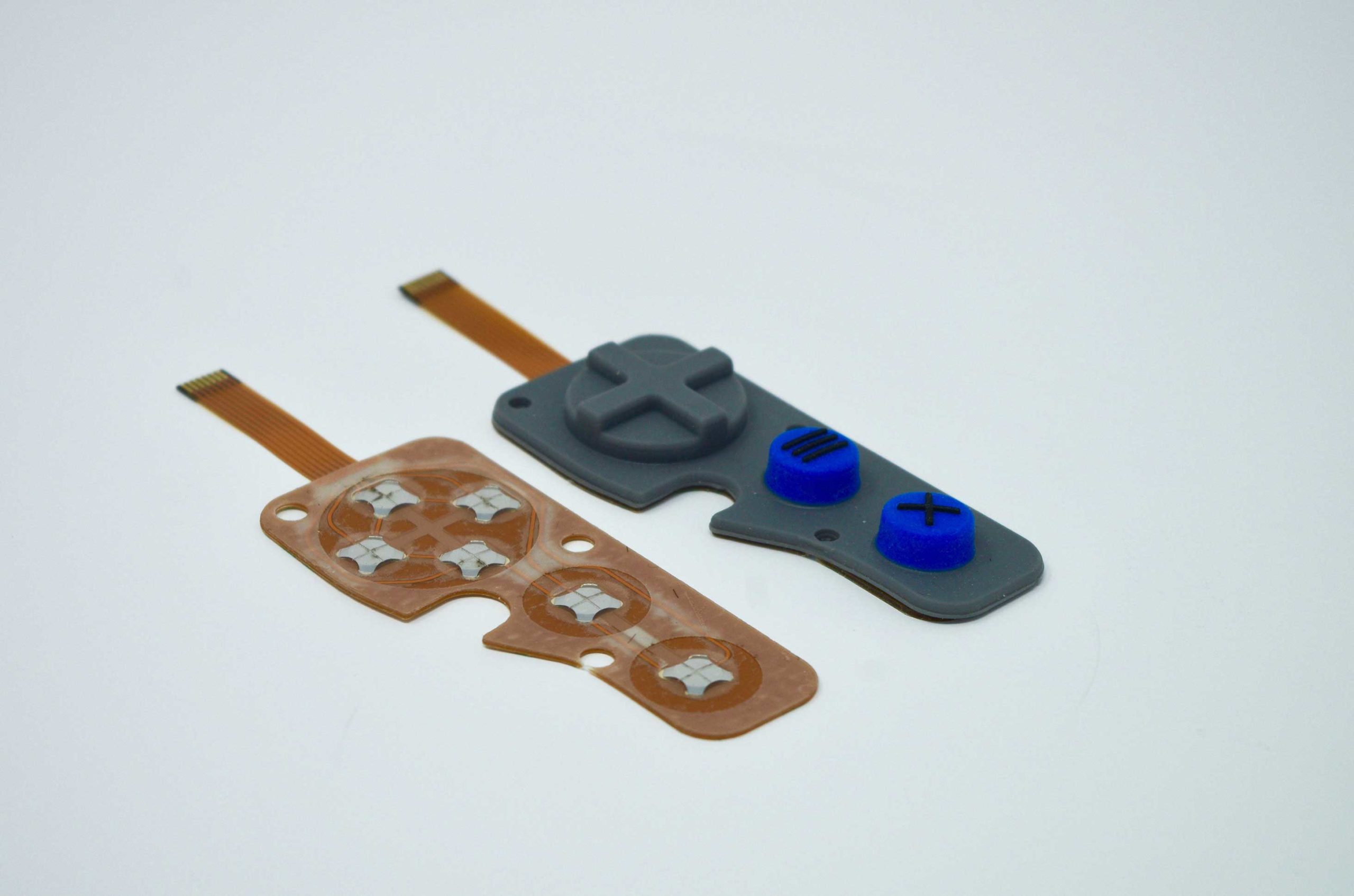

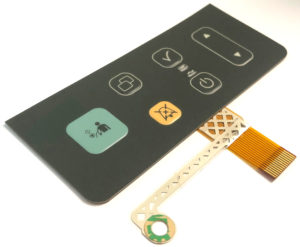

CSI Keyboards uses copper flex circuitry in the majority of our custom keypad designs due to its excellent dielectric strength, thermal stability, chemical resistance and flexibility. Copper flex, also known as Kapton circuits, have become the superior choice over printed silver especially for outdoor applications. A printed silver circuit can be replaced with a copper and polyimide construction with minimal additional cost. Copper flex circuitry construction designs offer a significant advantage over printed silver.

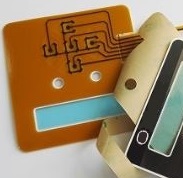

Copper Flex membrane switch panels are produced using polyimide (Kapton) as the base material. Copper flex keypad switches are manufactured by laminating a thin sheet of copper to a flexible film substrate. The copper is then chemically etched away, leaving the copper traces. An additional layer of polyimide is laminated to the circuit leaving the gold contacts exposed.

Advantages of copperflex over printed silver circuitry is as follows:

- Improved creasability – the ability to fold or crease without causing open circuits which you are susceptible to using silver ink

- Ability to put solder components directly on flex, better adhesion than bonding to silver ink

- Much more resistant to thermal shock

- No potential problems with silver migration

- Greater conductivity

- Lowering the closed loop resistance and switch bounce will be reduced by gold plating the contacts. We will have a gold to gold contact with no bounce versus silver to gold dome

- Applying stiffener to tail end using heat lamination versus cold lamination which provides better adhesion and better for pinning

- Ability to have a 0.5mm pitch vs. the 1.0mm minimum with printed silver

- Tighter trace routing capabilities

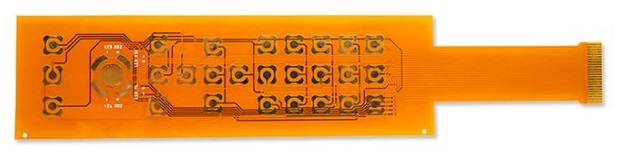

Single and Double Sided Flex Circuits

Single-sided flex circuits consist of a single copper conductor layer on a flexible dielectric film. These flex circuits can be fabricated with or without coverlayers.

Double-sided flex circuits consist of two copper layers encapsulated with dielectric, typically connected with a plated thru-hole. Can also be fabricated with or without coverlayers.

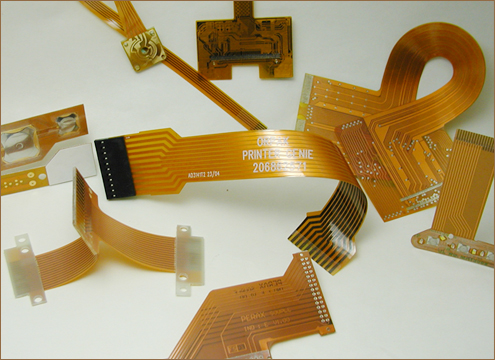

Multi Layer Flex Circuits

Multi-layer flex circuits consist of 3-6 copper layers encapsulated with dielectric, typically connected with a plated thru-hole.

Rigid Flex Circuits

Rigid flex circuits have conductors on both the flexible and rigid layers of the circuit. Plated thru holes extend between the flexible and rigid sections and electrically connect multiple conductor layers.