Mechanical Switches vs Membrane Switches

Keypads can generally be broken down into one of two different categories: membrane switches and mechanical switches. While their primary purpose is the same they are completely different solutions.

Membrane Switches

Mechanical Switches

So What’s the Difference?

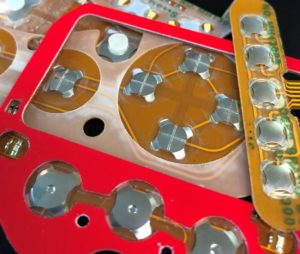

The main difference between mechanical switches and membrane switches is the overall construction. Membrane keypads are essentially assemblies that are not separate moving parts. They feature pressure pads on a flat circuit. Membrane keypads work by using an electrical contact underneath the keys’ surface. When a key is pressed, it makes contact with the circuit registering the key press. Membrane switches typically utilize metal domes to make contact and provide tactile feedback. Dome switch keypads use two circuit board traces in conjunction with a metal dome. Metal domes, which are typically made of stainless steel, are momentary switch contacts that provide tactility or “snap” when pressed. The domes become normally-open tactile switches when actuated on the circuit. More on domes switches can be found here.

Maintenance & Sealing

Another critical difference between mechanical and membrane switches is their maintenance requirements. Because membrane keypads are embedded into the components, there’s no way for dust, dirt and debris to enter the circuitry as there are no openings. As such, cleaning a membrane keypad is far easier and less time consuming than cleaning a mechanical keypad. It is also much easier to seal a membrane keypad versus a mechanical switch.

Cost

There is a false pretense that membrane keypads are more expensive than their mechanical counterpart, but this isn’t necessarily true. In actuality, membrane keypads typically cost less than mechanical switch solutions, making them an attractive option for customers with high volumes. Because the keys are all integrated together without moving parts, membrane keypads are easier to manufacture resulting in a lower price for the end consumer.