Membrane Switch Connector Options

Membrane switch connectors connect the keypad to the actual product, device or machine. Connectors consist of both contacts and molded plastic housings. Membrane switches are typically designed with flexible tails that are cut from the circuit material which is inserted or connected to a printed circuit board with a variety of connectors. Alternatively, the tail can be designed and prepared to connect with a Zero Insertion Force (ZIF) connector on the customer’s PCB. ZIF connectors have become extremely popular and industry norm. If the membrane switch is not flexible circuit based but instead, a PCB based keypad design, a flexible tail can be hot-bar soldered to the PCB or any connector can be soldered directly to the printed circuit board. Although both are rarely used in the modern era, solder tabs and discrete wires are both additional options.

Connector Options:

Most Common Options:

• Bare Tail: connects to .100” center ZIF style connector

• Female Standard Connector: connects to a .100” center, .025” square posted header

• Female Latching Connector: connects to a .100” center latching header

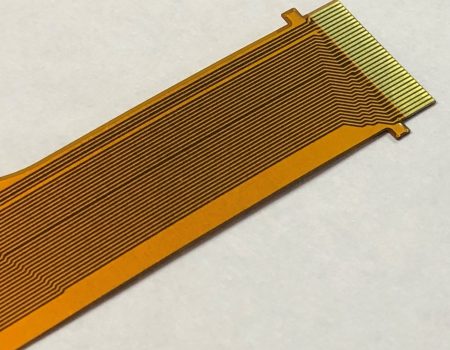

Bare Tail for ZIF Connector

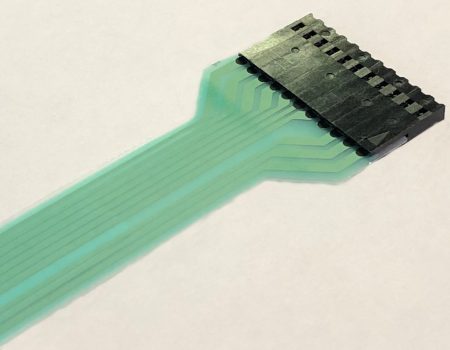

Female Standard Connector

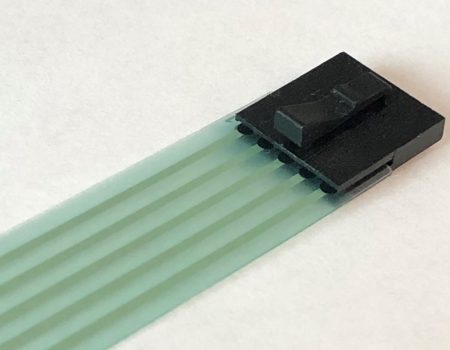

Female Latching Connector

- Male Standard Connector: interfaces to a .100” center female header

- Male Latching Connector: interfaces to a .100” center latching header

- Solder Tabs: .100” centers and can be directly soldered to PCB or wires

- Discrete Wires

ZIF Connectors

ZIF connectors are assembled to the PCB end and therefore there is no physical connector on your membrane switch side (the end of the flex tail is bare). ZIF connectors typically have a low profile, are lightweight, secure, and removable connections. ZIF connectors are appropriate for more complex applications and allow for higher levels of integration. The tail of the circuit is inserted into the ZIF connector to create the contact, and a stiffener is laminated under the tail to ensure stability and maintenance of the electrical contact. ZIF connectors may have anywhere from 2 to 30 positions on a single row, and distances of between 1mm and 2.54 mm are available.

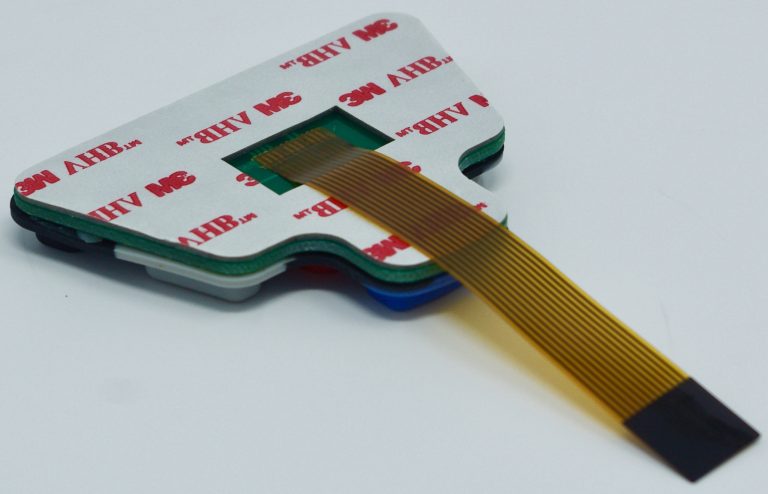

Crimpflex & Memcon Connectors

Crimpflex and Memcon connectors conform to Berg, Molex, and Amp membrane switch connecting specifications by utilizing common pins in a specific housing to meet connection requirements. The Crimpflex and Memcon crimping presses are dedicated to the manual and pneumatic crimping of male and female contacts and are known for their reliability, ruggedness, simplicity of use, speed, and precision. The contacts ensure mechanical retention and electrical contact by piercing the conductor in six points. The contacts are available in male, male solder tab, and female versions; the female contacts are selective gold or tin-plated. Standard housings are available in the OF series, which fits with the most common interfaces, or the OM series, which interfaces with cables and comes with an locking system that can be oriented to meet your specifications.

Hot Bar Soldered Tails

This type of connection has become very common with printed circuit board based membrane keypad and membrane switch designs. A copper flex tail is hot bar soldered directly to the PCB. The tail can then be inserted directly into a ZIF connector on the customer’s PCB. Allows for a lot more flexibility in the design and tolerance when plugging the tail into the board versus using a connector.

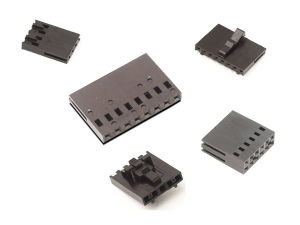

Male, Female, or Solder Tab Housings

These types of connectors are considered to be more reliable against heavy shock and vibration. They also are known for more ease of assembly. With a much larger connection, male, female, and solder connectors have pins crimped to the circuit and are available with many different housing features. The tail pitch is available in .100” spacing.