Backlighting

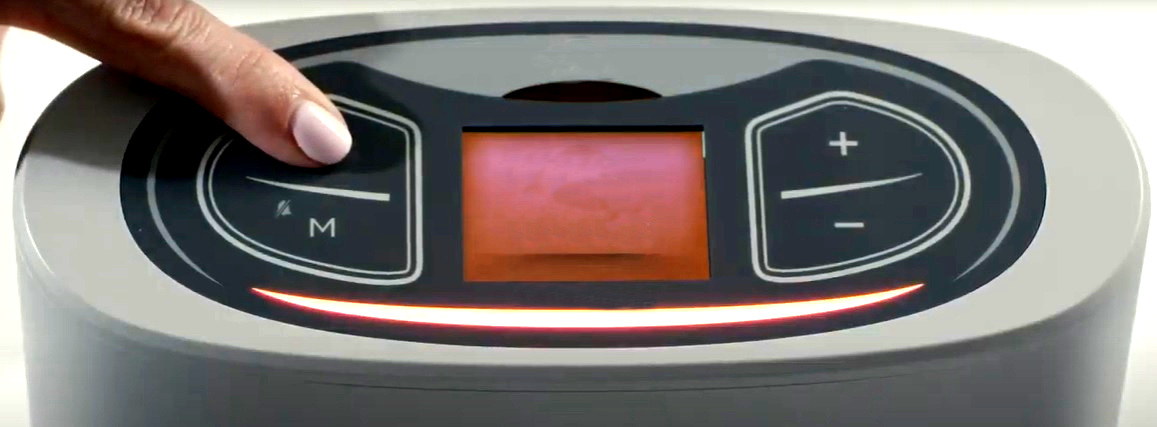

CSI Keyboards is a global leader in membrane switch backlighting and interface backlighting technology. Whether backlighting a logo, individual keys, or the entire interface surface, CSI will design and manufacture a backlit membrane keypad switches or backlit interface that will stand out both visually and aesthetically. CSI’s backlit products include: backlit human machine interfaces, backlit membrane switches, backlit elastomeric keypads and backlit panels or signage.

Backlit membrane switches are perfect for any industry and are often used in military and aerospace applications to help the user better interface with our customer’s product or instrument. A backlit membrane keypad or interface can also help a product stand out from the competition as it gives the keypad a sharper look and are excellent for low light environments.

Backlighting Considerations

Some things to keep in mind when considering the idea of backlighting your product: backlighting can increase both power consumption and heat production, two factors that influence the selection of backlighting technology. Some backlighting technologies are available today which require little power, ideal for both battery-powered devices and general applications in which minimizing power demands are desirable. Additionally, the availability of backlighting technology that produces little heat is generally valuable for most product designs and alleviates some thermal considerations for the functionality of various components, such as printed circuit boards.

Backlighting also plays a critical role in the visual appearance and aesthetics of not only the membrane switch, but the overall product. Backlit interfaces can really make your product “pop” and stand out from your competition.

Backlighting Options

LEDs

LEDs are the most popular and economical method for keyboard backlighting. LEDs are most commonly used to backlight keys, icons and symbols. LEDs are also typically used as indicator lights. A combination of LEDs, Light Guide Film and proprietary CSI backlighting methods can be designed to backlight the entire surface of a user interface.

Light Guide Film (LGF)

Light Guide Film is designed to evenly distribute light from top or side firing LEDs, providing bright, uniformed illumination. It also reduces the amount of LEDs needed, saving power consumption. More on light guide film technology below. The design and utilization of light guide film (LGF) technology has become one of the most common methods of interface backlighting. CSI Keyboards uses proprietary techniques to design the light guide film so it is optimized for light redirection and reflection giving the customer the brightest possible backlighting solution. Light guide film dots are also designed and implemented which allow for the optimization of light distribution to obtain maximum brightness and uniformity. Common problems that many of our competitors face are light leakage and hot spots. CSI’s backlighting designs prevent any light leakage and hot spots from occurring, and also result in much brighter light guide film and interface.

Electroluminescence (EL)

EL is applied on a very thin layer between the graphic overlay and the circuit. EL uses a printable ink deposit to illuminate the switch and provide a uniformed illumination.

Fiber Optics

Fiber Optics provide a flexible back lighting layer that can be incorporated between the graphic overlay and the circuit layer allowing the entire surface area of the membrane switch to be evenly backlit.

Membrane Switch Backlighting

CSI Keyboards has been backlighting membrane keyboards and user interfaces for over three decades. We’ve used backlighting techniques from the simplest LED membrane switch using a single colored LED indicator with a transparent smoked LED window (to hide LED from surface), to the most complicated multi-colored membrane keypad switch assembly. We can bring your product to life and make it truly stand out from your competition by backlighting keys, nomenclature, logos, perimeters, indicators, or the entire keypad.

Backlit Status Light Bar:

By utilizing side-firing LEDs and Light Guide Film (LGF), CSI Keyboards was able to design and develop a membrane switch with an LED light bar. The CSI Engineers used RGB LEDs, ensuring that they were mounted/located in areas on the PCB that would ensure optimal backlighting. The next step was designing the Light Guide Film ensuring the light guide prisms were designed for optimal backlighting and eliminating any chance for hot spots.

Blue Backlit Light Bar

Yellow Backlit Light Bar

Red Backlit Light Bar

Fiber Optic Backlighting:

Fiber Optic Backlighting provides a flexible and customizable back lighting layer that can be incorporated between the graphic overlay and the circuit layer allowing the entire surface area of the membrane switch to be evenly backlit. Fiber optics allow for a uniform and evenly distributed backlit surface.

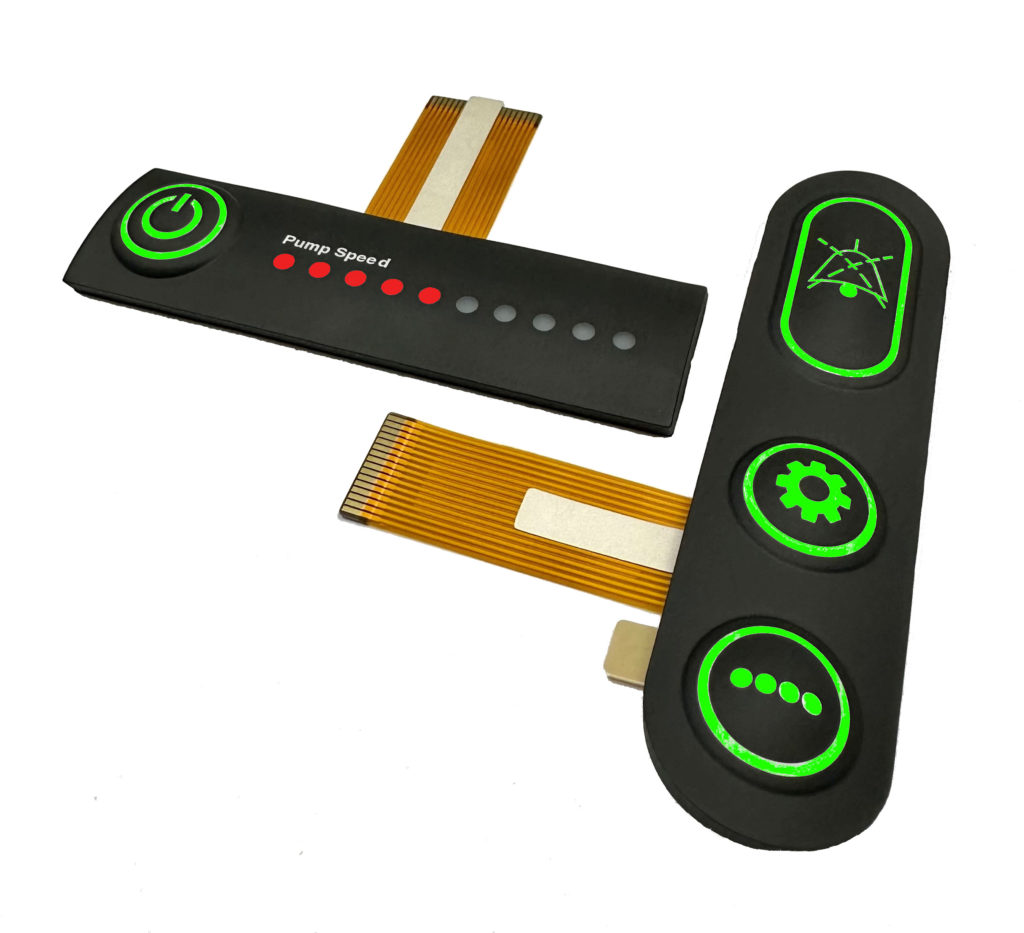

Rubber Switch Backlighting

When it comes to elastomeric keypad backlighting, CSI has both the knowledge and expertise to utilize and take advantage of molded silicone rubber which is an excellent conductor of light. CSI Keyboards utilizes laser etching and light pipe technology as some of our many techniques. As a leading rubber keypad manufacturer, CSI Keyboards uses many different technologies to backlight custom rubber keypads including but not limited to:

LEDs

The most popular and economical method for backlighting rubber keypads. LEDs are most commonly used to backlight keys, icons and symbols. LEDs are also typically used as indicator lights. A combination of LEDs, Light Guide Film and proprietary CSI backlighting methods can be designed to backlight the entire surface of a user interface.

Light Guide Film (LGF)

Designed to evenly distribute light from top or side firing LEDs, providing bright, uniformed illumination. It also reduces the amount of LEDs needed, saving power consumption. The design and utilization of light guide film (LGF) technology has become one of the most common methods of interface backlighting. CSI Keyboards uses proprietary techniques to design the light guide film so it is optimized for light redirection and reflection giving the customer the brightest possible backlighting solution. Light guide film dots are also designed and implemented which allow for the optimization of light distribution to obtain maximum brightness and uniformity. Common problems that many of our competitors face are light leakage and hot spots. CSI’s backlighting designs prevent any light leakage and hot spots from occurring, and also result in much brighter light guide film and interface.

Laser Etching

When a rubber keypad or rubber membrane switch calls for backlighting, you may often hear the term “laser etching” being used. Laser etching refers to a process in which a high powered laser is utilized to remove a layer or layers of paint on a keypad.

A standard rubber keypad is simply printed to add graphics or nomenclature. This method will suffice as long as the keypad is not backlit. It’s a cheap and easy way to create letters, numbers, and special characters on keys, making it the preferred choice among many companies. But in order to backlight molded rubber, the rubber must be laser etched: which is a newer, more advanced method for producing backlit nomenclature, graphics, indicators, etc.

The molded rubber typically starts off as a translucent, milky-like color and is then painted with opaque colors designed into the part. The rubber is then laser etched down to the translucent layer(s) of the keypad that will eventually be backlit with LEDs. The laser is carefully guided across the surface of the key, burning away paint in select areas. After the paint has been removed, it reveals the translucent layer below. The result is a contrasting translucent and opaque color, making the backlit areas pop with a higher level of crispness, brightness and visibility.

Laser etched keypads are extremely rugged and durable. The combination of molded light blocks inside the part and the laser etched nomenclature on the faceplate make for an unmatched backlit keypad.