The Benefits of Using Copper Flex Circuity vs. Printed Silver

CSI Keyboards uses copper flex circuitry in the majority of our custom keypad designs due to its excellent dielectric strength, thermal stability, chemical resistance and flexibility. Copper flex, also known as Kapton circuits, have become the superior choice over printed silver especially for outdoor applications.

A printed silver circuit can be replaced with a copper and polyimide construction with minimal additional cost. Copper flex circuitry construction designs offer a significant advantage over printed silver.

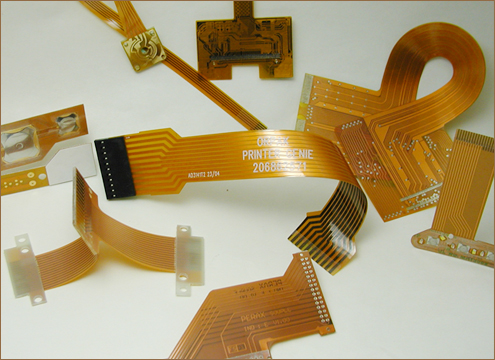

Copper Flex membrane switch panels are produced using polyimide (Kapton) as the base material. Copper flex keypad switches are manufactured by laminating a thin sheet of copper to a flexible film substrate. The copper is then chemically etched away, leaving the copper traces. An additional layer of polyimide is laminated to the circuit leaving the gold contacts exposed.

Advantages of Copper Flex Circuitry vs. Printed Silver

- Improved creasability – the ability to fold or crease without causing open circuits which you are susceptible to using silver ink

- Ability to put solder components directly on flex, better adhesion than bonding to silver ink

- Much more resistant to thermal shock

- No potential problems with silver migration

- Greater conductivity

- Lowering the closed loop resistance and switch bounce will be reduced by gold plating the contacts. We will have a gold to gold contact with no bounce versus silver to gold dome

- Applying stiffener to tail end using heat lamination versus cold lamination which provides better adhesion and better for pinning

- Ability to have a 0.5mm pitch vs. the 1.0mm minimum with printed silver

- Tighter trace routing capabilities

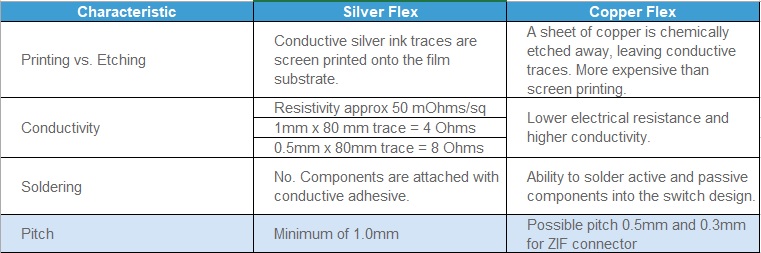

Printed Silver vs. Copper Flex

The Case Against Printed Silver - "Silver Migration"

The biggest case against using printed silver circuitry and thus using copper flex circuity is a phenomenon known as silver migration which occurs in microelectronics, components, PCB assemblies and membrane switches. Silver migration is the ionic movement of silver between two adjacent traces that inevitably results in a temporary electrical short.

Silver is a very active metal and is thus highly susceptible to silver migration or dendrite growth. Yet it is also a very cost effective metal for the electronic industry because of it’s conductively and usability. With the reduction or elimination of lead in electronics, silver is a very attractive choice because of its solderability and conductivity.

Silver Migration with Membrane Switches

Silver migration in membrane switches was a much bigger problem in the 1970’s and 1980’s; mainly because of the technical inability of the membrane switch manufacturers. In some cases these manufacturers were graphic screen printers who could screen print silver paste, but had little understanding of electronics or reliability issues associated with the electronics industry.

Today, with competent membrane switch manufacturers, silver migration is less of a problem. However, there are situations such as severe environments or design constraint issues where silver migration is still a risk. As in all aspects of electronics, the industry drive to reduce space and reduce costs with increased functionality continually pushes the envelope for designers and manufacturers of membrane switches.

Causes of Silver Migration

Two factors are typically required to create silver migration in a circuit using silver as the conductor:

1) A voltage potential between two traces.

2) The presence of moisture.

Ways to Reduce or Prevent Silver Migration

Some or all of the following solutions can be used to reduce or prevent the occurrence of silver migration.

- Modifying the silver composition with palladium or copper.

- Covering the silver traces with an inert coating such as a protective carbon layer and/or an overcoat dielectric.

- Increasing the conductor spacing between traces that have a voltage potential.

- Reducing the voltage.

- Preventing moisture penetration greatly reduces the risk of dendritic growth. Gasketing and sealing technology can stop the ambient penetration of moisture; elevated temperatures will make it necessary to utilize other methods to reduce migration.

- There are several areas of a membrane switch that are more susceptible to water damage because they are collection points for moisture or allow moisture to easily penetrate such as terminations, tail break-outs, areas with low adhesion