What is the Difference Between Flexible Circuit and PCB Based Membrane Switches?

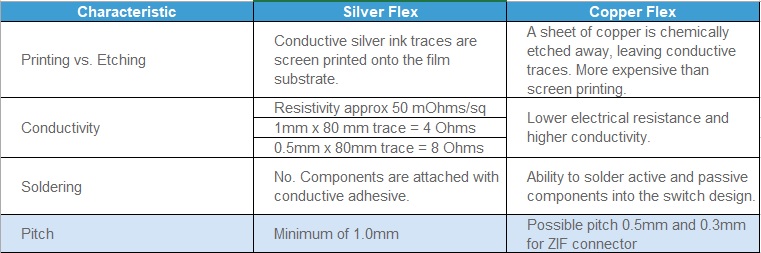

When designing a membrane switch, one of the most critical aspects that must be decided early-on in the design stage is the circuit type. The whole design and construction of the part is based around the type of circuitry that is used. The three types of circuitry options are: silver flexible circuits, copper flex circuits, or printed circuit board (PCB). If you are unsure as to what circuit is best for your application, CSI can work closely with you in proposing which option is ideal for the design.

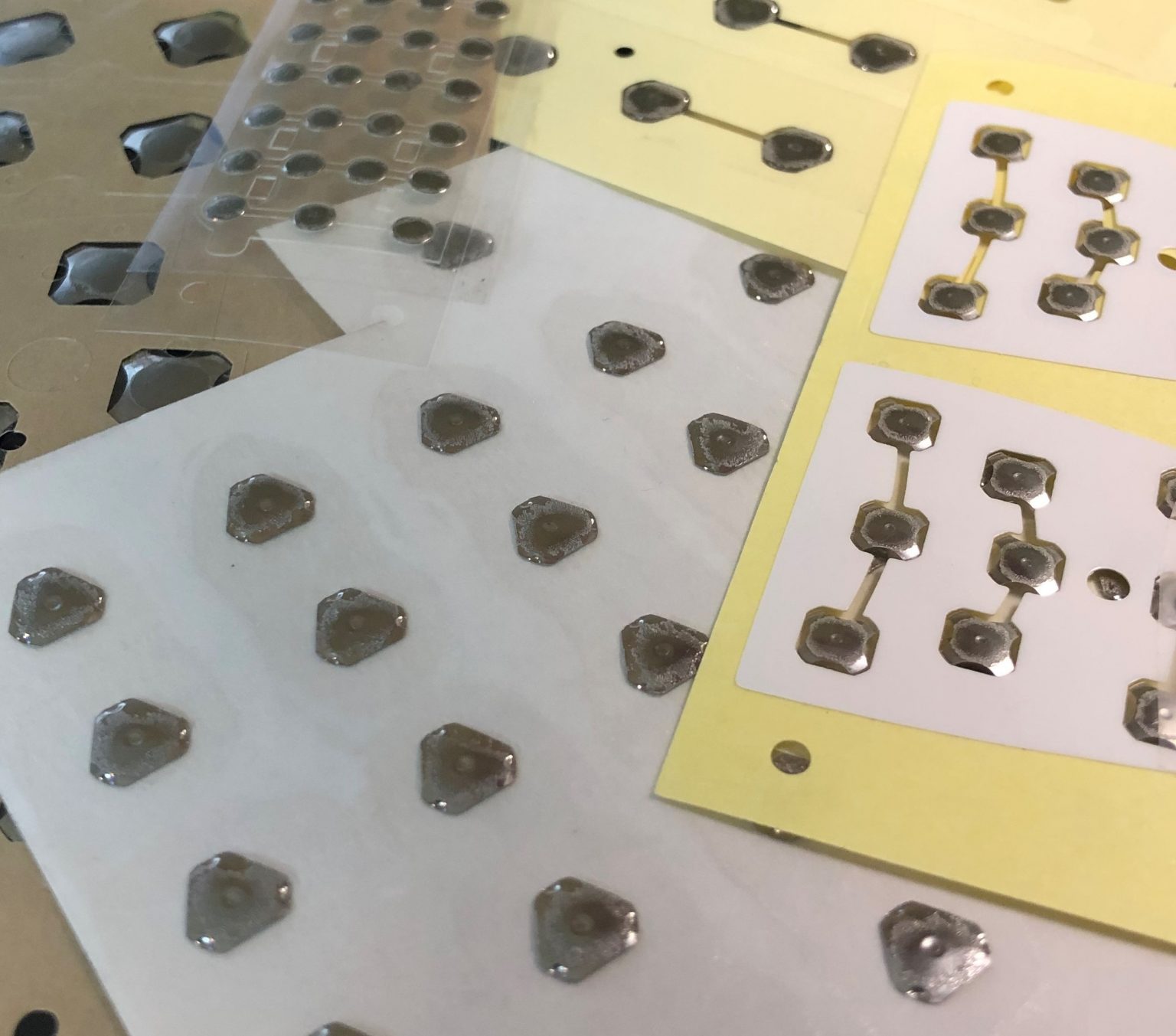

Silver Flexible Membrane Switches

Silver Flex membrane switch panels utilize screen-printed silver and carbon conductive inks printed on flexible polyester layers separated by an adhesive spacer. This is the most common design used in flexible, custom membrane keypads, offering a slim, space-saving design.

Silver Flexible circuity is also more cost-effective when compared to electromechanical switch assemblies and the process of screen-printing conductive silver inks onto a flexible, film substrate poses less potential threat to the environment compared to chemically etched copper.

Silver Flex membrane switches offer you a variety of design options:

- Tactile and non-tactile with either metal or polyester tactile domes

- Embedded LED’s

- Fiber Optic backlighting

- EL (Electroluminescent) backlighting

- Rigid backers such as aluminum and FR4

- EMI/RFI shielding

- Standard connectors on .100″ centers, or prepared for ZIF connections

Additionally, a Silver Flex membrane switch uses a graphic overlay, which also has a number of design options:

- Digital printing, screen-printing, or a combination of both

- Pillow or rim embossing

- Transparent and/or tinted display windows

- Selective textures

- UV hard-coat surface finishes

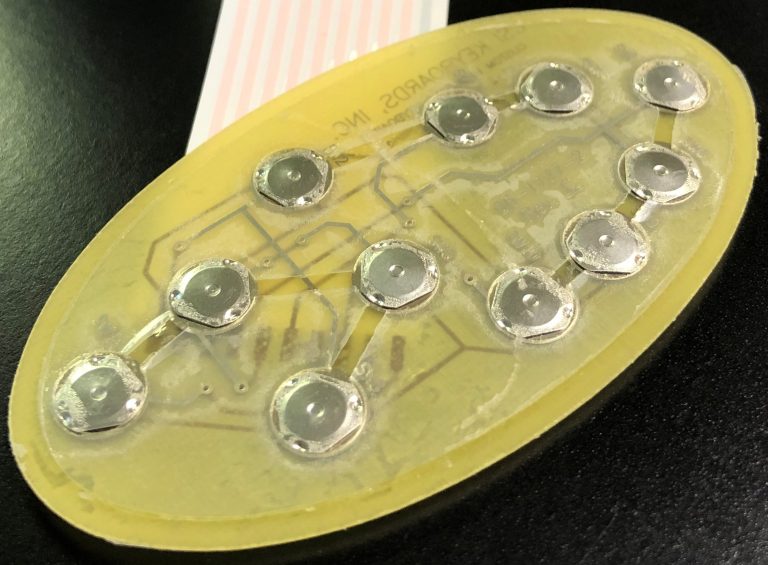

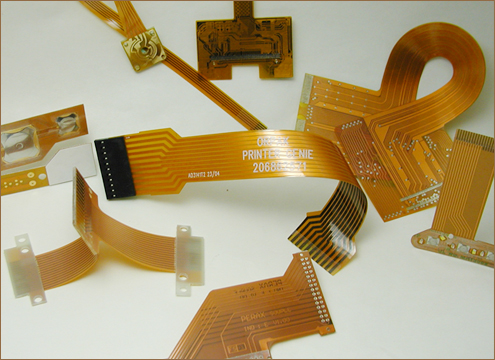

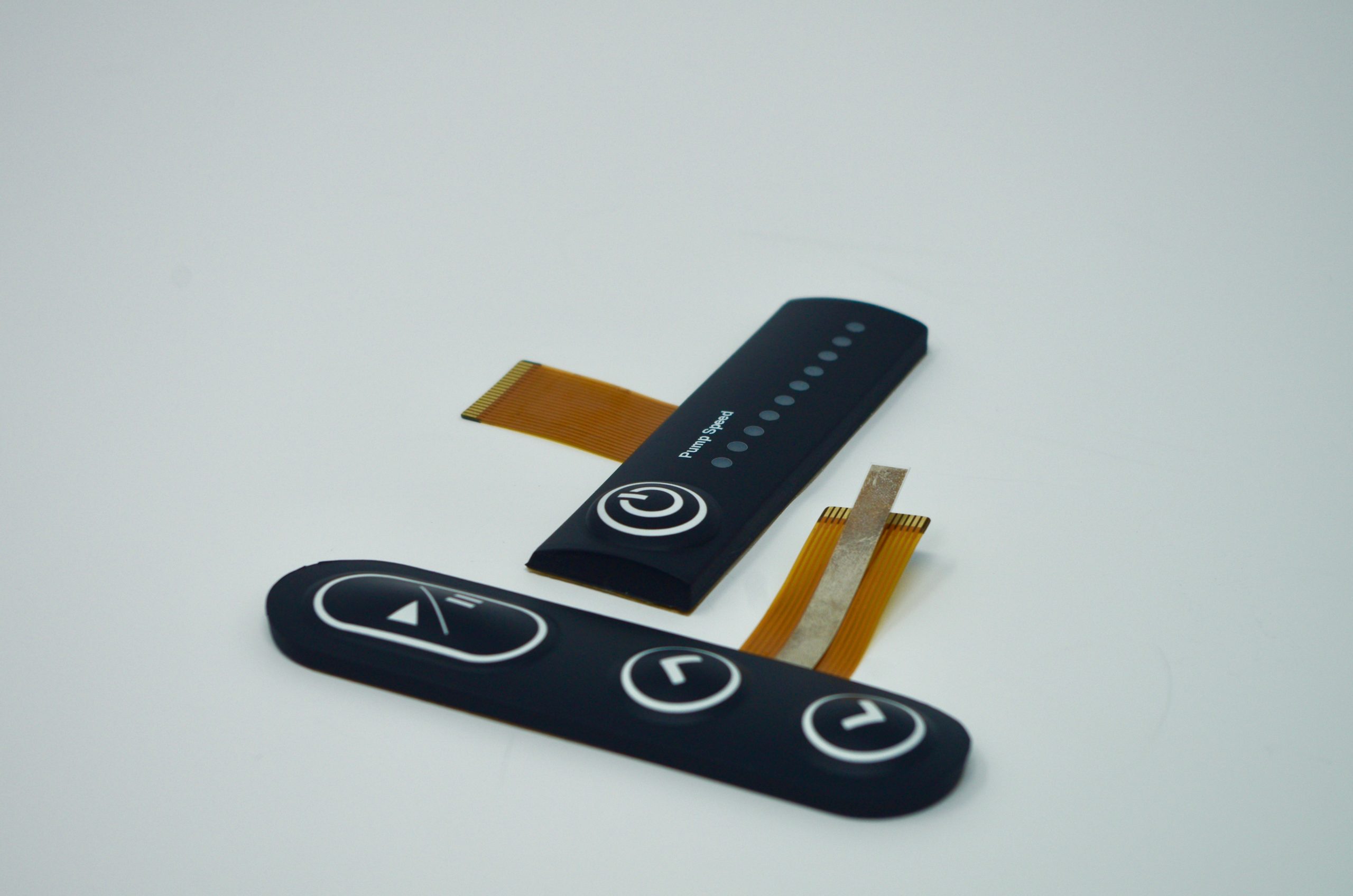

The Copper Flex Membrane Switch constructions are ideal for smaller designs, where space is at a premium, or where dense circuit patterns or trace routing limitations exist. Copper Flex membrane keypads utilize silver or copper layers which are laminated to a dielectric layer and etched away.

This switching technology combines the ability to accommodate the complex circuit patterns of a FR4 rigid printed circuit board with the flexibility of a membrane switch. Copper Flex keypads also have the advantage of being able to “hard” solder both active and passive components into the assembly, making it a good choice in high-vibration environments.

Copper Flex membrane switch panels can be produced using polyester or polyimide (Kapton) as the base material depending on your interface requirements. A very thin sheet of copper is laminated to the flexible film substrate then chemically etched away, leaving copper traces.

Copper Flex membrane switches offer you a variety of design options:

- Single and double sided designs

- Lower electrical resistance and higher conductivity vs. traditional Silver Flex membrane switches

- Tight trace routing capabilities

- Thin profile and flexibility of Silver Flex membrane switch

- Plating options can be tin-lead, nickel, or gold

- Tactile and non-tactile with either metal or polyester tactile domes

- LED’s and other components can be soldered

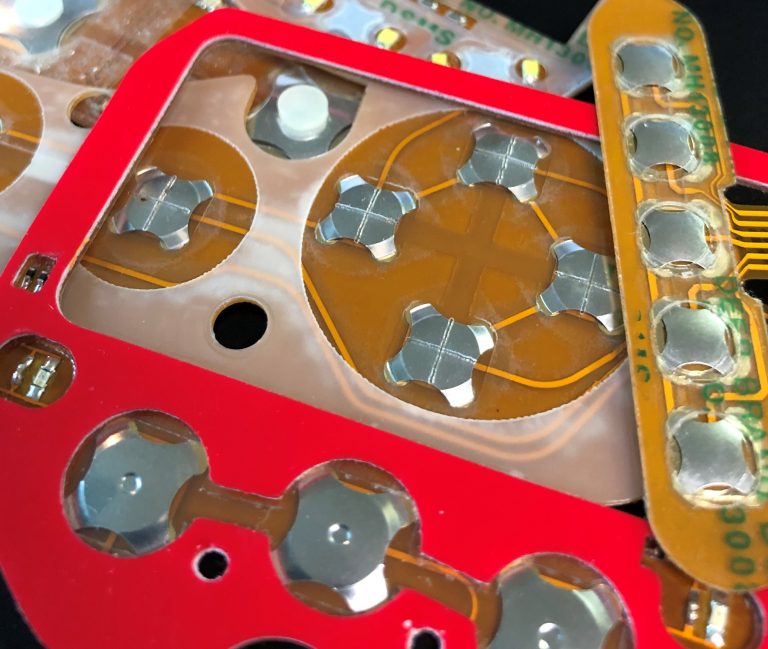

PCB Based Membrane Switches

The PCB Membrane Switch construction utilizes a printed circuit board (PCB) which can serve a dual purpose in your membrane switch design. PCB Switches are typically more costly than Silver Flex membrane keypads, but can accommodate dense circuit patterns and more complex circuit patterns compared to Silver Flex membrane keypads.

A PCB membrane switch also allows the electronic components to be “hard-soldered” into the PCB, whereas membrane switch components are placed using a polymer thick film conductive paste. With a PCB membrane switch, the PCB can serve as a rigid backer, and is also a very durable and reliable method to incorporate LED’s, resistors, LCD’s and other components.

PCB membrane keyboards offer you a variety of design options:

- Tactile and non-tactile with either metal or polyester tactile domes

- Pillow or rim-embossed graphic overlays

- Embedded LED’s that are soldered directly into the PCB

- Fiber Optic backlighting

- EL – (Electroluminescent backlighting)

- Rigid backers such as aluminum and FR4

- EMI/RFI shielding

- Unlimited choice of connectors, which can be soldered directly into the PCB