Sealing Methods for Rubber Keypads

When designing a product, one of the most critical considerations is sealing requirements. A properly sealed product prevents unwanted substance intrusion into the device. While internal components (most importantly electronics) are typically protected by the main enclosure, it is equally important that the keypad or interface area is also properly designed and sealed. Any weak-points related to the HMI or HMI area, can potentially allow for ingress of dust, liquids, and other substances that can cause permanent damage to the product.

The good news is that there are a few methods that can be designed into the HMI to completely prevent particulate ingress. Below are some of the most common types of sealing methods used in our keypad designs:

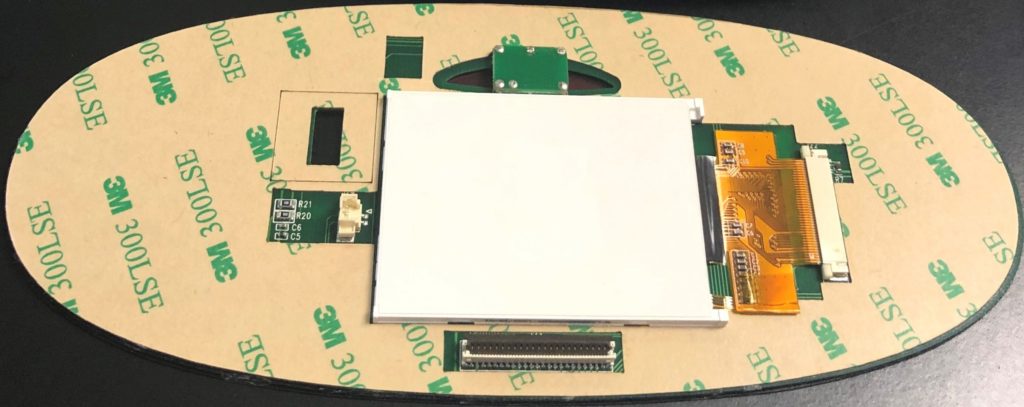

Perimeter or Frame Seal: One of the most common methods of sealing, this method involves designing a frame of adhesive that goes around the perimeter of the keypad preventing any liquid or chemical ingress. Because it requires a specific amount and type of adhesive for an effective seal, the available space on the bezel and under the overlay is an important consideration. It is also important that there are no components on the edge of the keypad in order to accommodate this frame of adhesive.

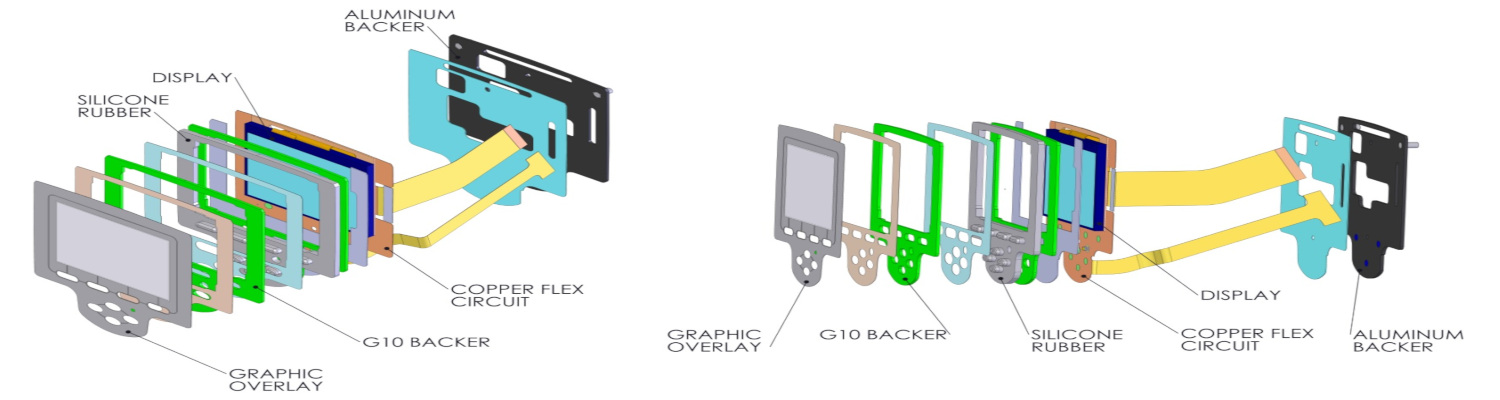

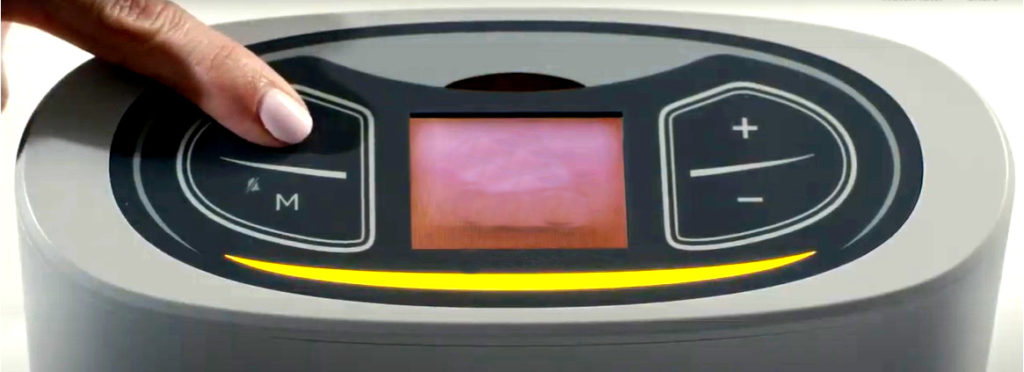

Compression Seal: When using a rubber keypad design, the elastomer can act as an excellent seal as it has great compression and gasket-like characteristics. The silicone rubber is molded to be compression sealed to the front of the part or compressed from the sides into a well where the keypad sits. The compressed rubber offers a high level of protection from liquids and chemicals.

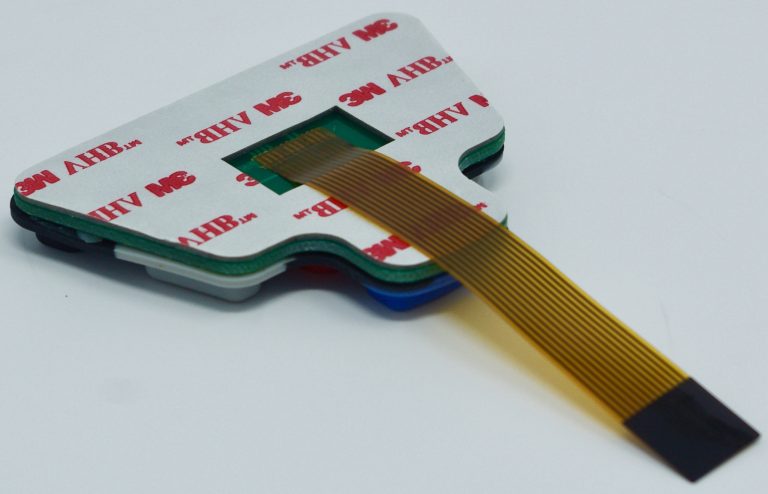

Wrap Around Seal: When using a rubber keypad design, the silicone rubber can be designed so the rubber actually wraps around the edge of the part, sealing off the front and edges of a device. The rubber wraps around the keypad’s internal layers, keeping the circuitry safe from any particulate ingress.

Front Surface Seal: If there are any openings in the front of the product’s bezel or case (typically around the perimeter of the part), front surface sealing can be an effective option. A sealant compound is dispensed into any openings or gaps in order to prevent particulates or liquids from entering. This is typically a “last resort” type of option, as the sealing process can be labor intensive and the final outcome not as aesthetically pleasing with a potting compound around the perimeter of the keypad.

Rear Surface Seal: Rear sealing involves sealing any openings behind the keypad, typically around tails or cables that come through the rear housing of the device.