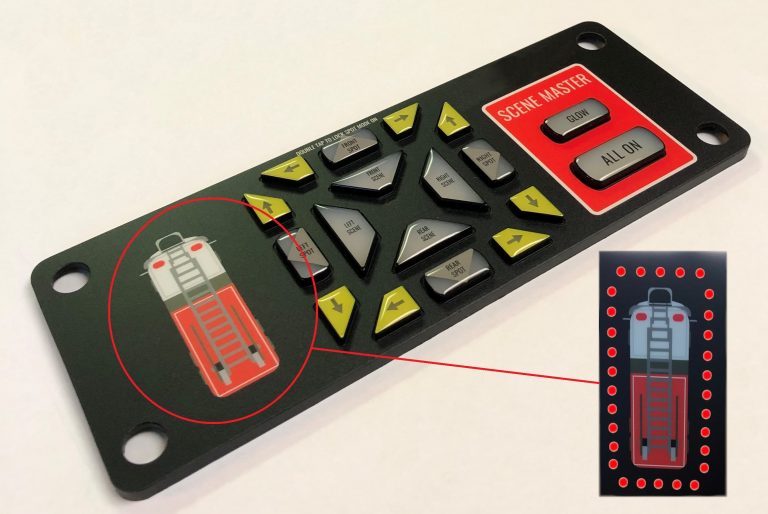

Designing a rubber keypad that is both backlit and completely sealed may seem like a daunting task, but that’s what the experts at CSI are here for! There are essentially two main components of the keypad assembly that must be properly designed: the rubber and the circuit. To better speak to the process, we will use the sample keypad on the right side of this post.

Rubber Decorating Process:

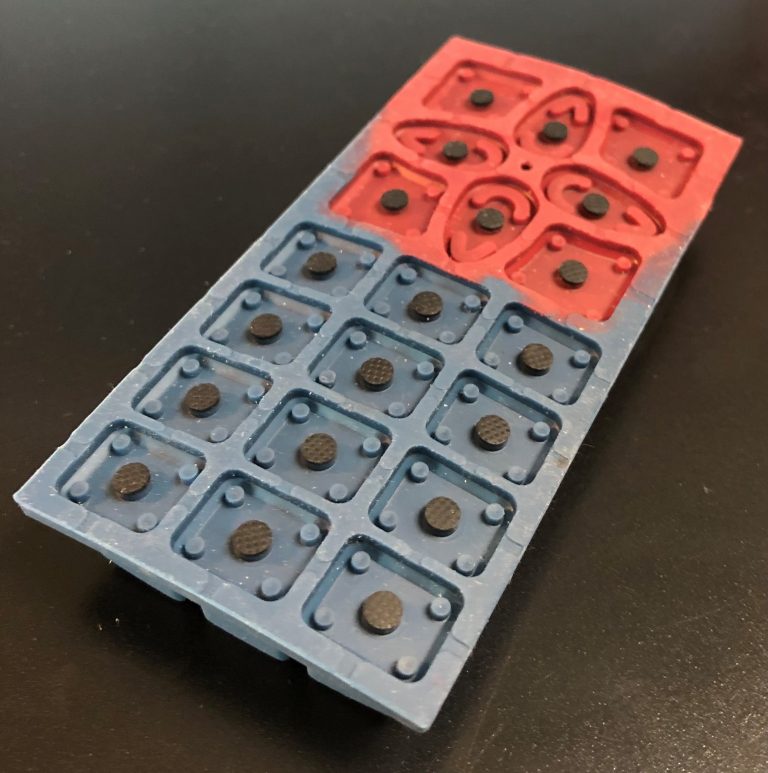

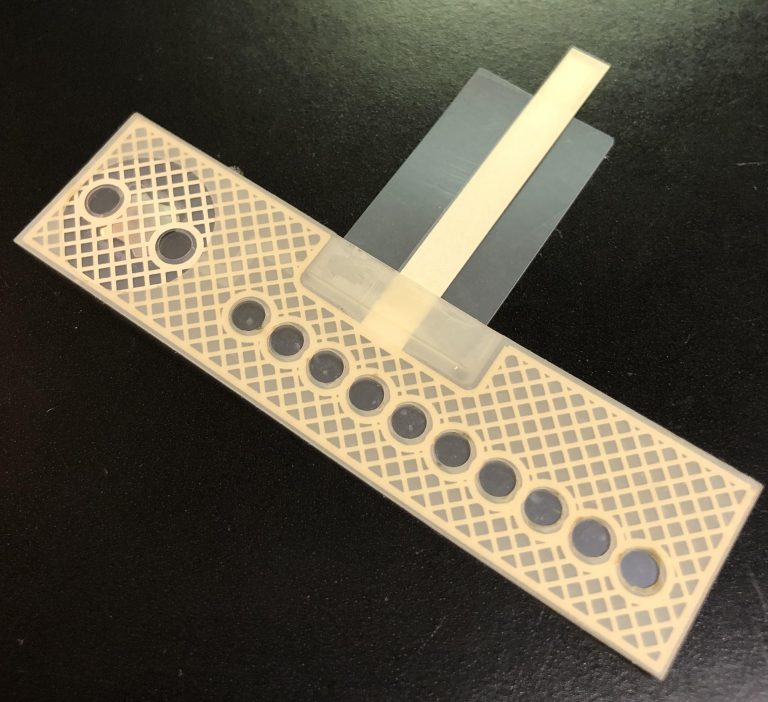

- The rubber starts off as a clear/milky translucent color (the color of the base material). The black portions of the keypad are rubber light blocks that are molded into the rubber to prevent light from bleeding into other portions of the keypad.

- The rubber is then sprayed translucent white.

- The rubber is then sprayed opaque black and then laser etched down to the translucent white material (for the power button) and hte clear base material (for the LED indicators) in the areas that are backlit.

- The rubber is carefully designed so that the actuators on the back of the keys press into the metal dome switches efficiently.

- The rubber is also designed so that it provides a seal. Silicone is typically used for gasketing in many products, so why not utilize it’s properties for the same reasons in your keypad?!

- The rubber is then sprayed with a UV resistant coating that protects the keypad from ultraviolet exposure, while also providing chemical resistance.

Additional Sealing Features:

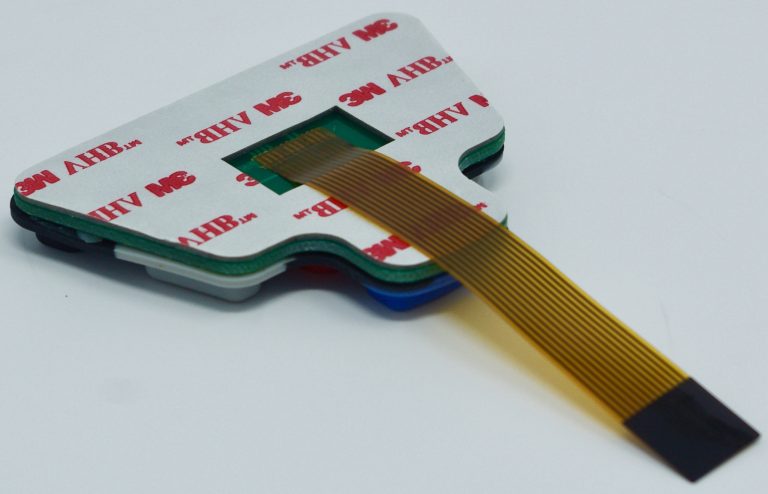

Copper Flex Circuitry, also known as polyimide Kapton circuitry, are used in the majority of CSI Keyboards’ keypad designs due to its excellent dielectric strength, thermal stability, chemical resistance and flexibility. Copper Flex membrane switch panels are produced using polyimide (Kapton) as the base material. Copper flex switches are manufactured by laminating a thin sheet of copper to a flexible film substrate. The copper is then chemically etched away, leaving the copper traces. An additional layer of polyimide is laminated to the circuit leaving the gold contacts exposed. Copper flex has become the superior choice over printed silver especially for outdoor applications. Copper flex circuitry construction designs offer a significant advantage over printed silver and a printed silver circuit can be replaced with a copper and polyimide construction with minimal additional cost.

Seal Frame is a perimeter frame of adhesive that protects your circuitry from any moisture ingress. It have proven to be as robust as other sealing methods such as perimeter temperature sealing and can be included in your design at minimal additional cost.

PU (polyurethane) Coating was applied, which protects the printed and molded colors on the rubber keypad, and also increases the longevity of the printing and graphics. This coating ensures a longer keypad life regardless of the environment. We also utilize a proprietary coating specially formulated for marine and outdoor applications which provides added protection against UV exposure.

Rear 3M 300LSE Adhesive was utilized, which is the top of the line adhesive specially formulated to provide high bond strength to surfaces. Our adhesives are resistant to humidity, UV, water, temperature, and chemicals.

EMI/RFI and ESD Protection is obtained using a metalized Mylar shield layer. A separate tail for the shielding layer was designed to connect to the housing or another mechanical piece already grounded. Another option could have been grounding to a trace on the interface panel and then routed to a grounded plane on the motherboard to carry the static charge away from any nearby conductive components.